SS304 stainless steel plate (0Cr19Ni9) is an austenitic stainless steel with the following characteristics:

Corrosion resistance

Contains 18%-20% chromium and 8%-10.5% nickel, and forms a dense chromium oxide protective film on the surface, which can resist corrosion from the atmosphere, fresh water, steam and weak acids (such as nitric acid and acetic acid), but is prone to pitting or stress corrosion cracking in chloride ion environments (such as seawater).

Mechanical properties

Tensile strength ≥520MPa, yield strength 205-210MPa, elongation ≥40%, hardness ≤187HB in the annealed state. Weak magnetism may be generated after cold processing (such as stamping and bending).

Application scenarios

Widely used in construction, chemical industry, food processing, medical equipment, kitchenware and other fields, such as the curtain wall of Shanghai Tower, pharmaceutical pipelines and thermos cups.

Processing characteristics

The work hardening effect is significant, and the hardness can reach HRB 92 after cold rolling, but it cannot be hardened by heat treatment.

Temperature range

The temperature range is -196℃ to 800℃, and it still maintains good corrosion resistance at high temperatures.

| Product Name | Stainless Steel Plate/Sheet |

| Padrão | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Técnica | Estirados a frio, laminados a quente, laminados a frio e outros. |

| Largura | 6-12 mm ou personalizável |

| Espessura | 1-120mm or Customizable |

| Comprimento | 1000 – 6000mm or Customizable |

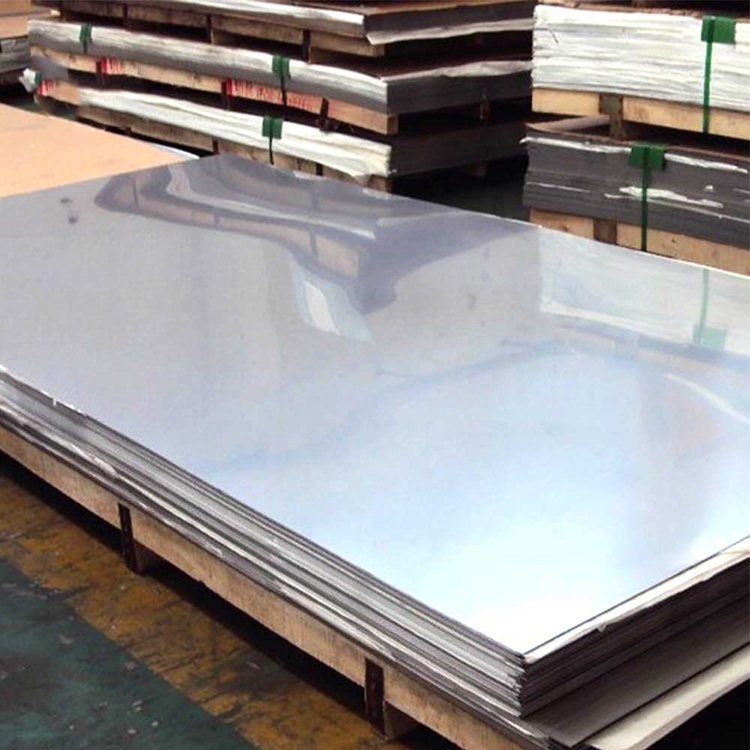

| Tratamento de superfície | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Origem | China |

| Código SH | 7211190000 |

| Prazo de entrega | {Tempo de entrega} |

| Serviço pós-venda | 24 horas em linha |

| Capacidade de produção | {Capacidade de produção} |

| Condições de preço | EXW, FOB, CIF, CRF, CNF or Others |

| Porta de carregamento | {Port} |

| Prazo de pagamento | TT, LC, Dinheiro, Paypal, DP, DA, Western Union ou outros. |

| Aplicação | 1. Architectural decoration. Such as exterior walls, curtain walls, ceilings, stair handrails, doors and windows, etc. |

| 2. Kitchen furniture. Such as kitchen stove, sink, etc. | |

| 3. Chemical equipment. Such as containers, pipelines, etc. | |

| 4. Food processing. Such as food containers, processing tables, etc. | |

| 5. Automobile manufacturing. Such as vehicle body, exhaust pipe, fuel tank, etc. | |

| 6. Electronic devices. Such as manufacturing casings, structural components, etc. for electronic devices. | |

| 7. Medical equipment. Such as surgical instruments, surgical instruments, medical utensils, etc. | |

| 8. Shipbuilding. Such as ship hulls, pipelines, equipment supports, etc. | |

| Embalagem | Pacote, saco de PVC, cinto de nylon, braçadeira de cabo, pacote padrão de exportação em condições de navegar ou como pedido. |

| Serviço de processamento | Dobragem, Soldadura, Desbobinagem, Puncionamento, Corte e outros. |

| Tolerância | ±1% |

| MOQ | {MOQ} |

Composição do aço inoxidável

O aço é uma liga de ferro e carbono. Os aços inoxidáveis são aços que contêm pelo menos 10,5% de crómio, menos de 1,2% de carbono e outros elementos de liga. A resistência à corrosão do aço inoxidável e

As propriedades mecânicas podem ser melhoradas pela adição de outros elementos, como o níquel, o molibdénio, o titânio, o nióbio, o manganês, etc.

| Grau | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Seleção da superfície