Corrosion resistance

Although the corrosion resistance of 409 stainless steel is not as good as that of austenitic stainless steel such as 304 stainless steel, it performs relatively well in high temperature and oxidizing environments. Appropriate protective measures can effectively extend its service life.

Thermal stability

409 stainless steel has good thermal stability and can maintain stable performance in high temperature environments. This makes it widely used in high temperature environments such as automotive exhaust systems.

Weldability

409 stainless steel has good weldability and is suitable for various welding processes. After welding, the strength and toughness of the material can still be maintained at a high level.

Cost advantage

Compared with other types of stainless steel, the production cost of 409 stainless steel is relatively low, so in some cost-sensitive fields, 409 stainless steel has become a good choice.

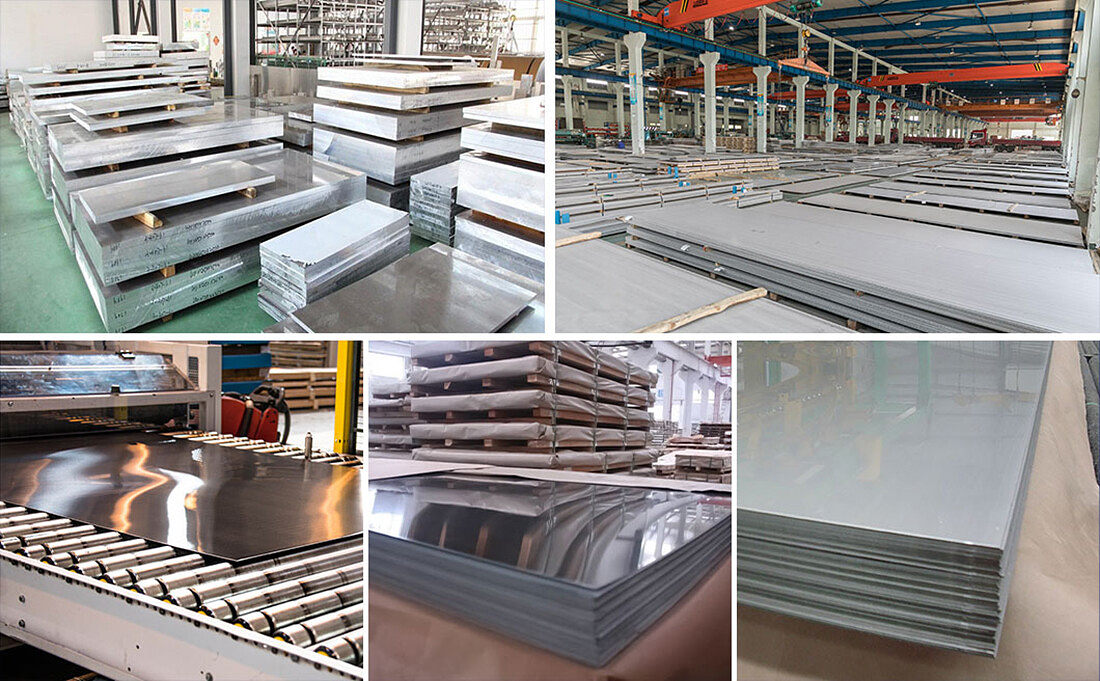

| Product Name | Stainless Steel Plate/Sheet |

| Padrão | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Técnica | Estirados a frio, laminados a quente, laminados a frio e outros. |

| Largura | 6-12 mm ou personalizável |

| Espessura | 1-120mm or Customizable |

| Comprimento | 1000 – 6000mm or Customizable |

| Tratamento de superfície | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Origem | China |

| Código SH | 7211190000 |

| Prazo de entrega | {Tempo de entrega} |

| Serviço pós-venda | 24 horas em linha |

| Capacidade de produção | {Capacidade de produção} |

| Condições de preço | EXW, FOB, CIF, CRF, CNF or Others |

| Porta de carregamento | {Port} |

| Prazo de pagamento | TT, LC, Dinheiro, Paypal, DP, DA, Western Union ou outros. |

| Aplicação | 1. Architectural decoration. Such as exterior walls, curtain walls, ceilings, stair handrails, doors and windows, etc. |

| 2. Kitchen furniture. Such as kitchen stove, sink, etc. | |

| 3. Chemical equipment. Such as containers, pipelines, etc. | |

| 4. Food processing. Such as food containers, processing tables, etc. | |

| 5. Automobile manufacturing. Such as vehicle body, exhaust pipe, fuel tank, etc. | |

| 6. Electronic devices. Such as manufacturing casings, structural components, etc. for electronic devices. | |

| 7. Medical equipment. Such as surgical instruments, surgical instruments, medical utensils, etc. | |

| 8. Shipbuilding. Such as ship hulls, pipelines, equipment supports, etc. | |

| Embalagem | Pacote, saco de PVC, cinto de nylon, braçadeira de cabo, pacote padrão de exportação em condições de navegar ou como pedido. |

| Serviço de processamento | Dobragem, Soldadura, Desbobinagem, Puncionamento, Corte e outros. |

| Tolerância | ±1% |

| MOQ | {MOQ} |

Composição do aço inoxidável

O aço é uma liga de ferro e carbono. Os aços inoxidáveis são aços que contêm pelo menos 10,5% de crómio, menos de 1,2% de carbono e outros elementos de liga. A resistência à corrosão do aço inoxidável e

As propriedades mecânicas podem ser melhoradas pela adição de outros elementos, como o níquel, o molibdénio, o titânio, o nióbio, o manganês, etc.

| Grau | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Seleção da superfície