The main features of SS316 (SUS316) stainless steel are as follows:

Corrosion resistance

Contains molybdenum (Mo) elements, excellent corrosion resistance, especially strong pitting resistance in chloride environments, better than SS304 stainless steel. It is stable in seawater and acidic/alkaline media, suitable for corrosive scenes such as chemical industry and ocean.

Mechanical properties

High temperature strength and tensile properties are outstanding, it can be used continuously below 1700℃, and still maintain oxidation resistance in high temperature environments of 871-899℃. It has good work hardening and is non-magnetic in the solid solution state.

Processing and maintenance

Cold-rolled products have high surface gloss, excellent welding performance and no tendency to knife-edge corrosion. Maintenance should avoid contact with strong alkaline substances (such as chlorine bleach), and regular cleaning can extend the service life.

Application scenarios

Widely used in fields with high requirements for hygiene and corrosion resistance, such as nuclear fuel recovery equipment, chemical pipelines, oil and gas transportation, and food and medical equipment.

| Product Name | Stainless Steel Plate/Sheet |

| Padrão | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Técnica | Estirados a frio, laminados a quente, laminados a frio e outros. |

| Largura | 6-12 mm ou personalizável |

| Espessura | 1-120mm or Customizable |

| Comprimento | 1000 – 6000mm or Customizable |

| Tratamento de superfície | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Origem | China |

| Código SH | 7211190000 |

| Prazo de entrega | {Tempo de entrega} |

| Serviço pós-venda | 24 horas em linha |

| Capacidade de produção | {Capacidade de produção} |

| Condições de preço | EXW, FOB, CIF, CRF, CNF or Others |

| Porta de carregamento | {Port} |

| Prazo de pagamento | TT, LC, Dinheiro, Paypal, DP, DA, Western Union ou outros. |

| Aplicação | 1. Architectural decoration. Such as exterior walls, curtain walls, ceilings, stair handrails, doors and windows, etc. |

| 2. Kitchen furniture. Such as kitchen stove, sink, etc. | |

| 3. Chemical equipment. Such as containers, pipelines, etc. | |

| 4. Food processing. Such as food containers, processing tables, etc. | |

| 5. Automobile manufacturing. Such as vehicle body, exhaust pipe, fuel tank, etc. | |

| 6. Electronic devices. Such as manufacturing casings, structural components, etc. for electronic devices. | |

| 7. Medical equipment. Such as surgical instruments, surgical instruments, medical utensils, etc. | |

| 8. Shipbuilding. Such as ship hulls, pipelines, equipment supports, etc. | |

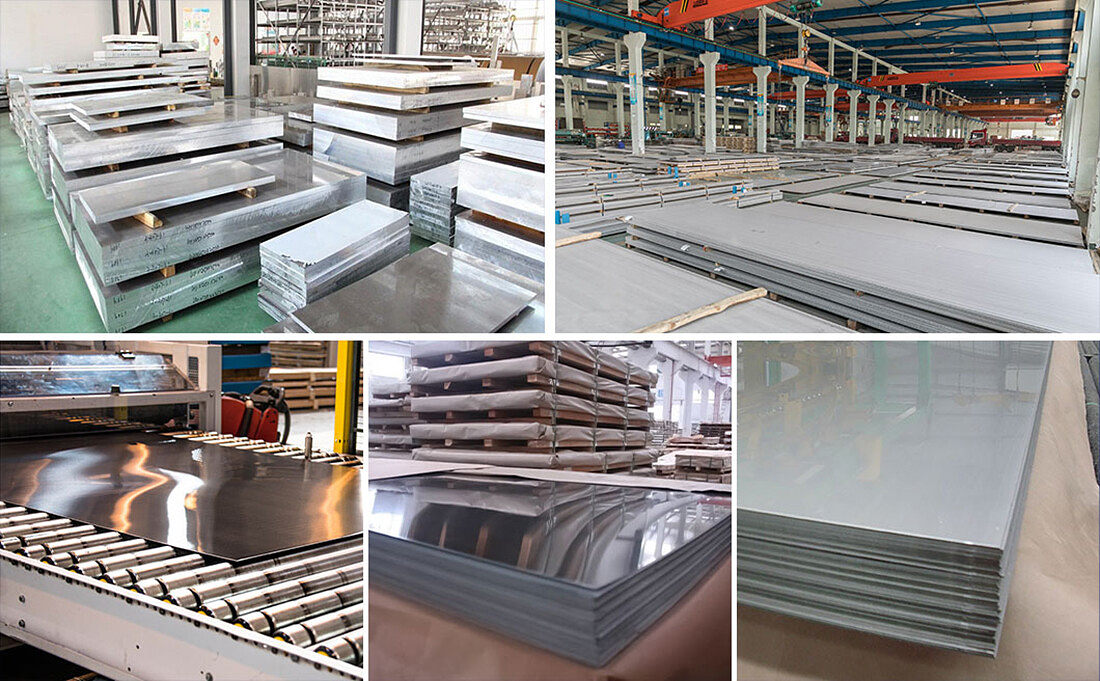

| Embalagem | Pacote, saco de PVC, cinto de nylon, braçadeira de cabo, pacote padrão de exportação em condições de navegar ou como pedido. |

| Serviço de processamento | Dobragem, Soldadura, Desbobinagem, Puncionamento, Corte e outros. |

| Tolerância | ±1% |

| MOQ | {MOQ} |

Composição do aço inoxidável

O aço é uma liga de ferro e carbono. Os aços inoxidáveis são aços que contêm pelo menos 10,5% de crómio, menos de 1,2% de carbono e outros elementos de liga. A resistência à corrosão do aço inoxidável e

As propriedades mecânicas podem ser melhoradas pela adição de outros elementos, como o níquel, o molibdénio, o titânio, o nióbio, o manganês, etc.

| Grau | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Seleção da superfície