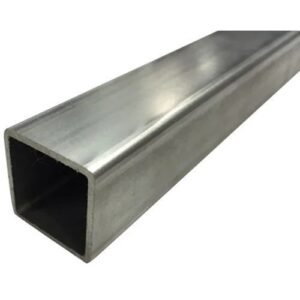

The characteristics of SS321 stainless steel pipe are as follows:

High temperature resistance: SS321 stainless steel has excellent high temperature resistance and can withstand corrosion and oxidation in high temperature environment for a long time.

Corrosion resistance: SS321 stainless steel has excellent corrosion resistance and can resist corrosion in many chemical environments, including organic acids, alkalis and solvents.

Oxidation resistance: SS321 stainless steel has good oxidation resistance, can resist high temperature oxidation and extend service life.

Processing performance: SS321 stainless steel has good plasticity and weldability, and is easy to process into various shapes and sizes.

Mechanical properties: SS321 stainless steel has high tensile strength, yield strength and impact toughness, suitable for various engineering and structural applications.

Chemical element composition content: The chemical element composition content of SS321 stainless steel includes chromium (Cr), nickel (Ni), iron (Fe) and titanium (Ti). The proportion and combination of these elements give SUS321 stainless steel high temperature resistance, corrosion resistance and oxidation resistance.

Characteristics at high temperatures: SS321 has excellent resistance to oxidation and corrosion, and has good creep strength. It is mainly used in oil refining equipment, pressure vessel pipelines, radiation superheaters, bellows and high-temperature heat treatment equipment.

Resistance to intergranular corrosion: Due to the addition of titanium, SS321 stainless steel has better resistance to intergranular corrosion and high-temperature strength

| Product Name | Stainless Steel Pipe/Tube |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Technique | Cold drawn, Hot rolled, Cold rolled and Others. |

| Side shape | Round, square, rectangular,etc. |

| Outer Diameter | 20mm-1200mm or Customizable |

| Thickness | 6-3000mm or Customizable |

| Length | 1-12m or Customizable |

| Surface Treatment | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Type | Seamless, Welded. |

| Origin | China |

| HS Code | 7304319000 |

| Delivery Time | {Delivery Time} |

| After-sales Service | 24 hours online. |

| Production Capacity | {Production Capacity} |

| Price Terms | EXW, FOB, CIF, CRF, CNF or Others. |

| Loading Port | {Port} |

| Section Shape | Round, Square, Rectangular, etc. |

| Payment Term | TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

| Application | 1. Tableware, cabinets, indoor pipelines, water heaters, boilers, bathtubs |

| 2. Automotive parts | |

| 3.Medicale quipment, building materials, chemicals, food industry, agriculture, ship components, etc. | |

| Packaging | Bundle, PVC Bag, Nylon Belt, Cable Tie, Standard export seaworthy package or as Request. |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting and Others. |

| Tolerance | ±1% |

| MOQ | {MOQ} |

Composition of Stainless Steel

Steel is an alloy of iron and carbon. Stainless steels are steels containing at least 10.5% chromium, less than 1.2% carbon and other alloying elements. Stainless steel’s corrosion resistance and

mechanical properties can be further enhanced by adding other elements, such as nickel, molybdenum, titanium, niobium, manganese, etc.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |