Corrosion resistance

Good acid and alkali resistance, but in the case of low nickel content, the corrosion resistance is significantly weaker than 304 stainless steel, and long-term contact with humid or salty environment may rust.

Physical properties

Density: 7.81 g/cm³

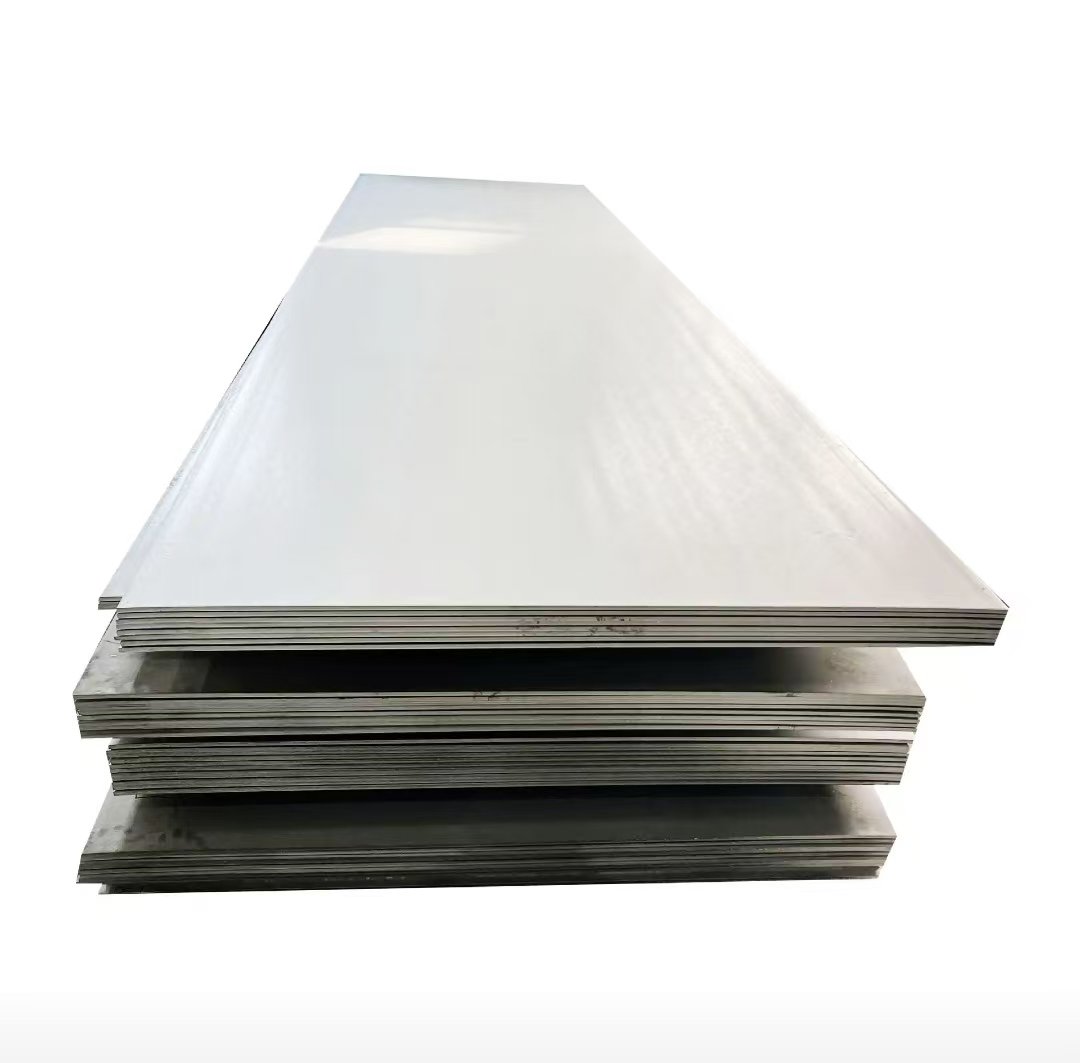

Polishing performance: Smooth surface without bubbles and pinholes, suitable for decorative purposes.

Mechanical properties: High strength, but slightly worse toughness than 304, with more outstanding tensile strength and hardness.

Applicable scenarios

Mainly used for the manufacture of precision parts such as watch cases, watch strap bottom covers, and also suitable for the production of decorative tubes, industrial tubes and shallow drawing products.

Chemical composition

Contains 16.0-18.0% chromium, 3.5-5.5% nickel, high manganese content (5.5-7.5%), carbon content ≤0.15%, and strict control of impurity elements such as sulfur and phosphorus.

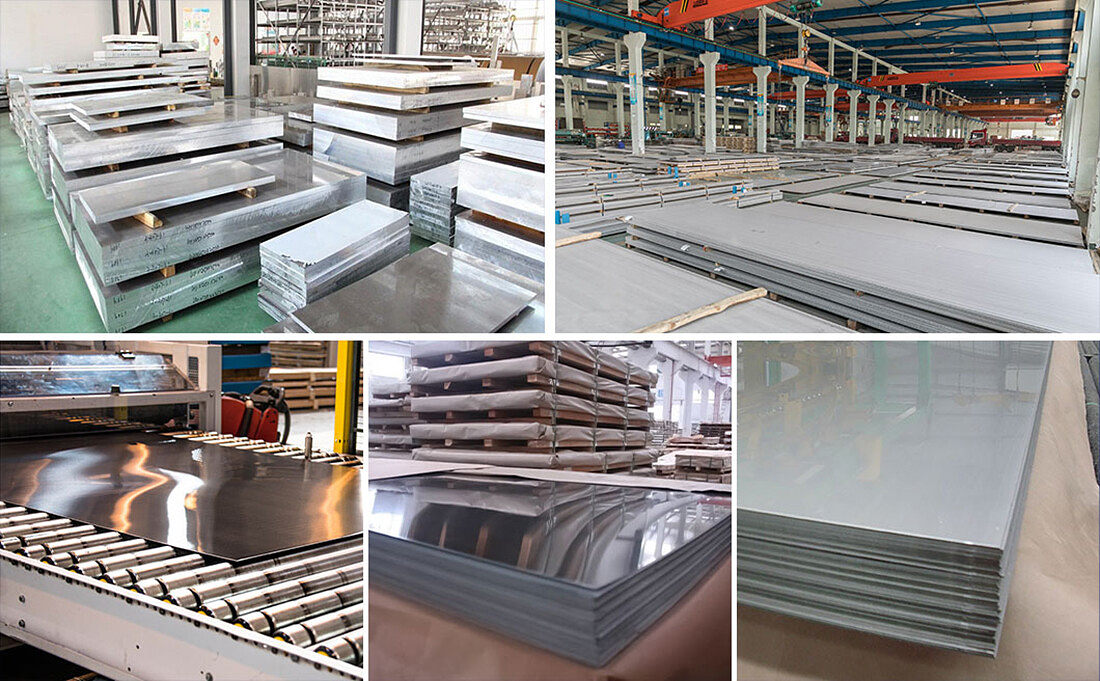

| Product Name | Stainless Steel Plate/Sheet |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Matériau | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Technique | Etiré à froid, laminé à chaud, laminé à froid et autres. |

| Largeur | 6-12mm ou personnalisable |

| Épaisseur | 1-120mm or Customizable |

| Longueur | 1000 – 6000mm or Customizable |

| Traitement de surface | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Origine | Chine |

| Code SH | 7211190000 |

| Délai de livraison | {Délai de livraison} |

| Service après-vente | 24 heures en ligne |

| Capacité de production | {Capacité de production} |

| Conditions de prix | EXW, FOB, CIF, CRF, CNF or Others |

| Port de chargement | {Port} |

| Délai de paiement | TT, LC, Cash, Paypal, DP, DA, Western Union ou autres. |

| Application | 1. Architectural decoration. Such as exterior walls, curtain walls, ceilings, stair handrails, doors and windows, etc. |

| 2. Kitchen furniture. Such as kitchen stove, sink, etc. | |

| 3. Chemical equipment. Such as containers, pipelines, etc. | |

| 4. Food processing. Such as food containers, processing tables, etc. | |

| 5. Automobile manufacturing. Such as vehicle body, exhaust pipe, fuel tank, etc. | |

| 6. Electronic devices. Such as manufacturing casings, structural components, etc. for electronic devices. | |

| 7. Medical equipment. Such as surgical instruments, surgical instruments, medical utensils, etc. | |

| 8. Shipbuilding. Such as ship hulls, pipelines, equipment supports, etc. | |

| Emballage | Emballage, sac en PVC, ceinture en nylon, serre-câble, emballage maritime standard pour l'exportation ou selon la demande. |

| Service de traitement | Pliage, soudage, décochage, poinçonnage, découpage et autres. |

| Tolérance | ±1% |

| MOQ | {MOQ} |

Composition de l'acier inoxydable

L'acier est un alliage de fer et de carbone. Les aciers inoxydables sont des aciers contenant au moins 10,5% de chrome, moins de 1,2% de carbone et d'autres éléments d'alliage. La résistance à la corrosion de l'acier inoxydable et

Les propriétés mécaniques peuvent être encore améliorées par l'ajout d'autres éléments, tels que le nickel, le molybdène, le titane, le niobium, le manganèse, etc.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Sélection de la surface