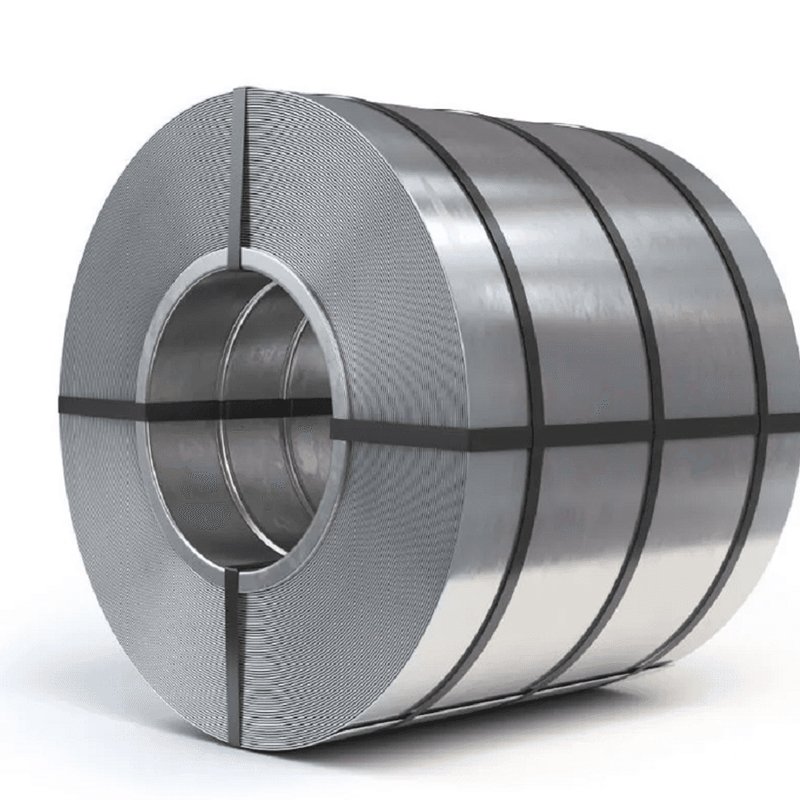

The characteristics of SS409 stainless steel coil mainly include the following points:

Low cost: SS409 stainless steel is one of the cheapest models currently (British and American), which makes it have obvious advantages in cost control.

Corrosion resistance: Although not as good as other high-end stainless steels, SS409 still has certain corrosion resistance, especially in dry environments.

High temperature performance: It has good high temperature oxidation resistance and is suitable for use in high temperature environments.

Mechanical properties: SS409 stainless steel has certain strength and hardness, which can meet the needs of general machinery and building structures.

Processing performance: The material has good processing performance and can be processed by various processing processes, such as film pasting, casting, opening, stretching, welding, drilling, stamping, laser cutting, forging, etc.

Application range: SS409 stainless steel coil is widely used in automobile exhaust pipes, construction, chemical industry and other industries, as well as solar energy, metal products, household appliances and other fields

| Product Name | Stainless Steel Coil/Strip |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Technique | Cold drawn, Hot rolled, Cold rolled and Others. |

| Width | 6-12mm or Customizable |

| Thickness | 1-12mm or Customizable |

| Length | 1000 – 6000mm or Customizable |

| Surface Treatment | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Origin | China |

| HS Code | 7219131200 |

| Delivery Time | {Delivery Time} |

| After-sales Service | 24 hours online |

| Production Capacity | {Production Capacity} |

| Price Terms | EXW, FOB, CIF, CRF, CNF or Others. |

| Loading Port | {Port} |

| Payment Term | TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

| Application | 1. Tableware, cabinets, indoor pipelines, water heaters, boilers, bathtubs |

| 2. Automotive parts | |

| 3.Medicale quipment, building materials, chemicals, food industry, agriculture, ship components, etc. | |

| Packaging | Bundle, PVC Bag, Nylon Belt, Cable Tie, Standard export seaworthy package or as Request. |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting and Others. |

| Tolerance | ±1% |

| MOQ | {MOQ} |

Composition of Stainless Steel

Steel is an alloy of iron and carbon. Stainless steels are steels containing at least 10.5% chromium, less than 1.2% carbon and other alloying elements. Stainless steel’s corrosion resistance and

mechanical properties can be further enhanced by adding other elements, such as nickel, molybdenum, titanium, niobium, manganese, etc.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Surface Selection