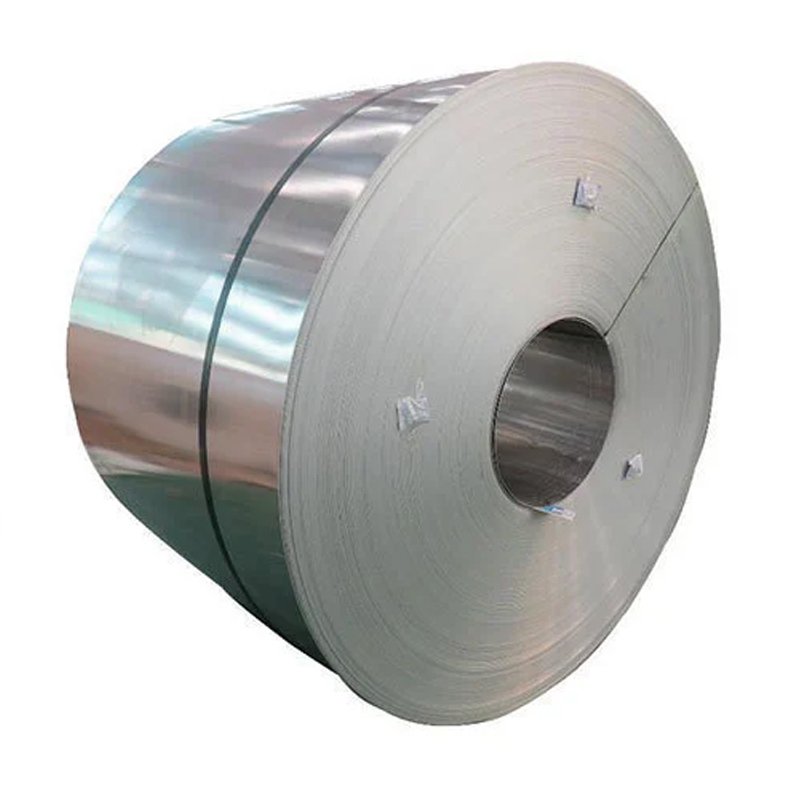

The main features of SS 201 stainless steel strip are as follows:

Material characteristics: SS 201 stainless steel is a chromium-manganese austenitic stainless steel, containing a large amount of manganese, as well as a certain amount of chromium, carbon and other small amounts of elements. It has certain acid and alkali resistance, high density, no bubbles, no pinholes after polishing, etc.1.

Performance characteristics: The hot and cold processing performance and welding performance of SS 201 stainless steel strip are relatively poor, and the sensitivity to hot cracks is strong. It has high strength and is suitable for applications such as stainless steel straps, clips, brackets and cable ties41.

Price factors: Due to the low nickel content in SS 201 stainless steel, its price is usually about half that of 304 stainless steel.

| Nom du produit | Bobine/bande en acier inoxydable |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Matériau | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Technique | Etiré à froid, laminé à chaud, laminé à froid et autres. |

| Largeur | 6-12mm ou personnalisable |

| Épaisseur | 1-12mm ou personnalisable |

| Longueur | 1000 - 6000mm ou personnalisable |

| Traitement de surface | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Origine | Chine |

| Code SH | 7219131200 |

| Délai de livraison | {Délai de livraison} |

| Service après-vente | 24 heures en ligne |

| Capacité de production | {Capacité de production} |

| Conditions de prix | EXW, FOB, CIF, CRF, CNF ou autres. |

| Port de chargement | {Port} |

| Délai de paiement | TT, LC, Cash, Paypal, DP, DA, Western Union ou autres. |

| Application | 1. Vaisselle, armoires, canalisations intérieures, chauffe-eau, chaudières, baignoires |

| 2. Pièces automobiles | |

| 3. équipements médicaux, matériaux de construction, produits chimiques, industrie alimentaire, agriculture, composants de navires, etc. | |

| Emballage | Emballage, sac en PVC, ceinture en nylon, serre-câble, emballage maritime standard pour l'exportation ou selon la demande. |

| Service de traitement | Pliage, soudage, décochage, poinçonnage, découpage et autres. |

| Tolérance | ±1% |

| MOQ | {MOQ} |

Composition de l'acier inoxydable

L'acier est un alliage de fer et de carbone. Les aciers inoxydables sont des aciers contenant au moins 10,5% de chrome, moins de 1,2% de carbone et d'autres éléments d'alliage. La résistance à la corrosion de l'acier inoxydable et

Les propriétés mécaniques peuvent être encore améliorées par l'ajout d'autres éléments, tels que le nickel, le molybdène, le titane, le niobium, le manganèse, etc.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Sélection de la surface