Features of 409 stainless steel angle steel:

Corrosion resistance:

409 stainless steel has excellent exhaust gas and atmospheric corrosion resistance, which is better than 410 martensitic grade stainless steel with 12% chromium content and 3CR12. However, its corrosion resistance is lower than 430 grade steel with 17% chromium.

High temperature resistance:

409 stainless steel can withstand temperatures up to 675°C during continuous operation and up to 815°C anti-scaling under intermittent conditions. These temperatures are related to specific service environments.

Mechanical properties:

409 stainless steel has medium strength, good formability and overall cost-effectiveness.

Cost-effectiveness:

409 stainless steel is one of the cheapest types of ferritic stainless steel and is commonly used as automobile exhaust pipes.

Environmental protection:

409 stainless steel is an environmentally friendly material that can be recycled and reused. Major automobile manufacturers use 100% stainless steel in exhaust systems.

Wide application:

409 stainless steel is widely used in automobile exhaust systems, construction, machinery and other fields.

Welding performance:

409 stainless steel can use 430 and 409 grade filler electrodes or welding rods during welding, but AS1554.6 strongly recommends the use of 309 grade welds or welding rods. In order to reduce grain growth, care should be taken to weld 409 stainless steel with the least amount of heat.

Grain structure:

409 stainless steel has almost no α→γ phase transformation from high temperature to low temperature, so the grains grow easily, coarse ferrite structure appears, and the strength is low.

Chemical composition:

409 stainless steel contains 11% chromium, which is the minimum amount to form a passive surface film that makes stainless steel corrosion-resistant.

Surface treatment:

The surface of 409 stainless steel is susceptible to mild corrosion, which limits the use of steel for decorative purposes.

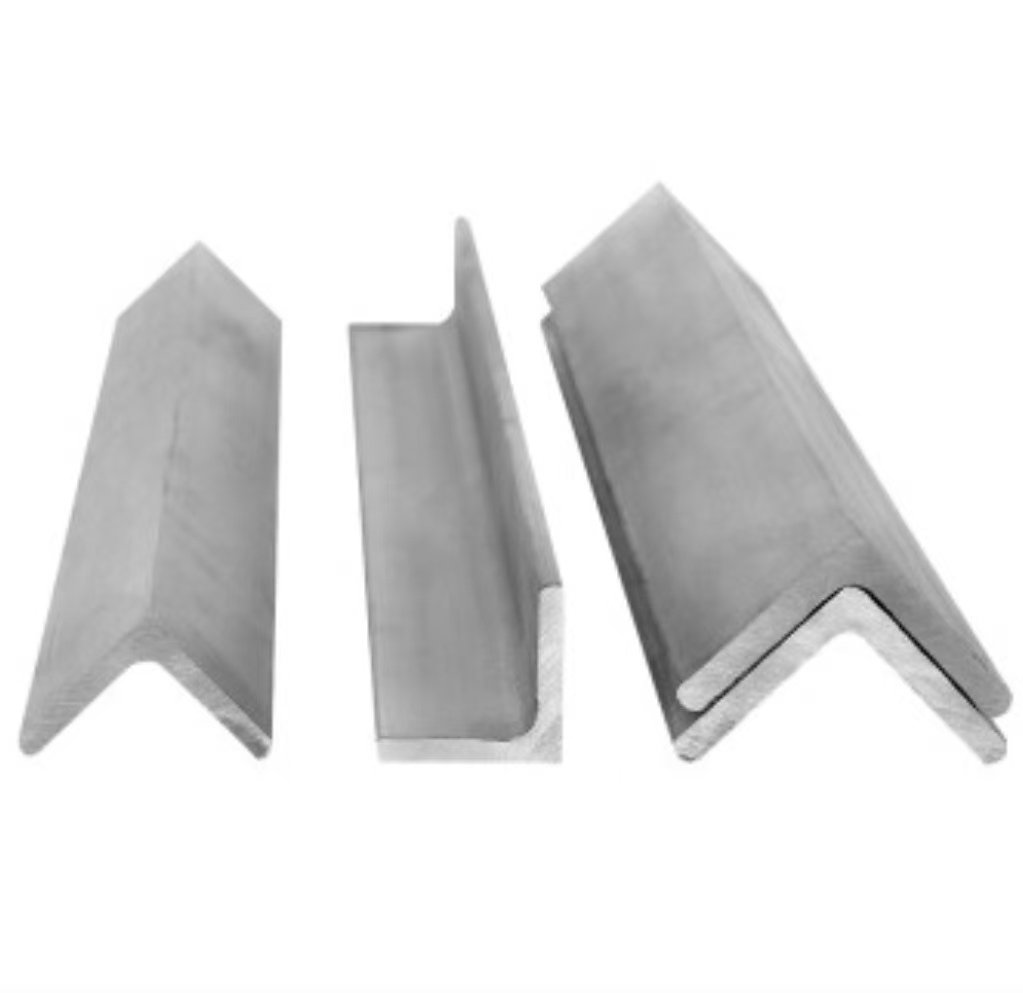

| Item Name | Stainless Steel Angle Bar | |

| Standard | AISI,ASTM,BS,DIN,GB,JIS, etc | |

| Matériau | 201, 304, 304S, 316, 316L, etc… | |

| Épaisseur | 3mm – 24mm or customized | |

| Equal Angle | Type: | 2#-20# |

| Size: | 20-200MM or customized | |

| Épaisseur | 3.0-24MM or customized | |

| Weight | 0.597-71.168kg/M | |

| Unequal Angle | Type | 2.5*1.6-20*12.5# |

| Size | 25*16-200*125mm or customized | |

| Long side | 20-200mm or customized | |

| Short side | ||

| Épaisseur | 3- 24mm or customized | |

| Weight | 1.687-43.588kg/m | |

| Longueur | 1-12m or as customer request | |

| Technique | Hot rolled/Cold rolled | |