Corrosion resistance

It performs well in oxidizing media (such as dilute nitric acid and dilute sulfuric acid), and also has good corrosion resistance to seawater and chloride solutions, but has poor corrosion resistance in alkaline media.

High temperature resistance

It can maintain stable performance at 427-816°C (800-1500°F), and the addition of titanium improves the resistance to intergranular corrosion at high temperatures.

Creep resistance

Ordinary 321 stainless steel may creep under long-term use at high temperatures, while high-carbon versions (such as 321H) show stronger creep resistance and are suitable for high-temperature environments.

Mechanical properties

Hardness: Brinell hardness about 201-217 HB, Rockwell hardness 85-92 HRB

Density: about 7.9 g/cm³

Melting point: 1375-1400°C

Application scenarios

Mainly used in industrial fields such as corrosion-resistant pipes, containers, and heat exchangers. Ordinary 321 stainless steel is suitable for medium and low temperature environments, while 321H is used in higher temperature scenarios (such as boilers and steam pipes)

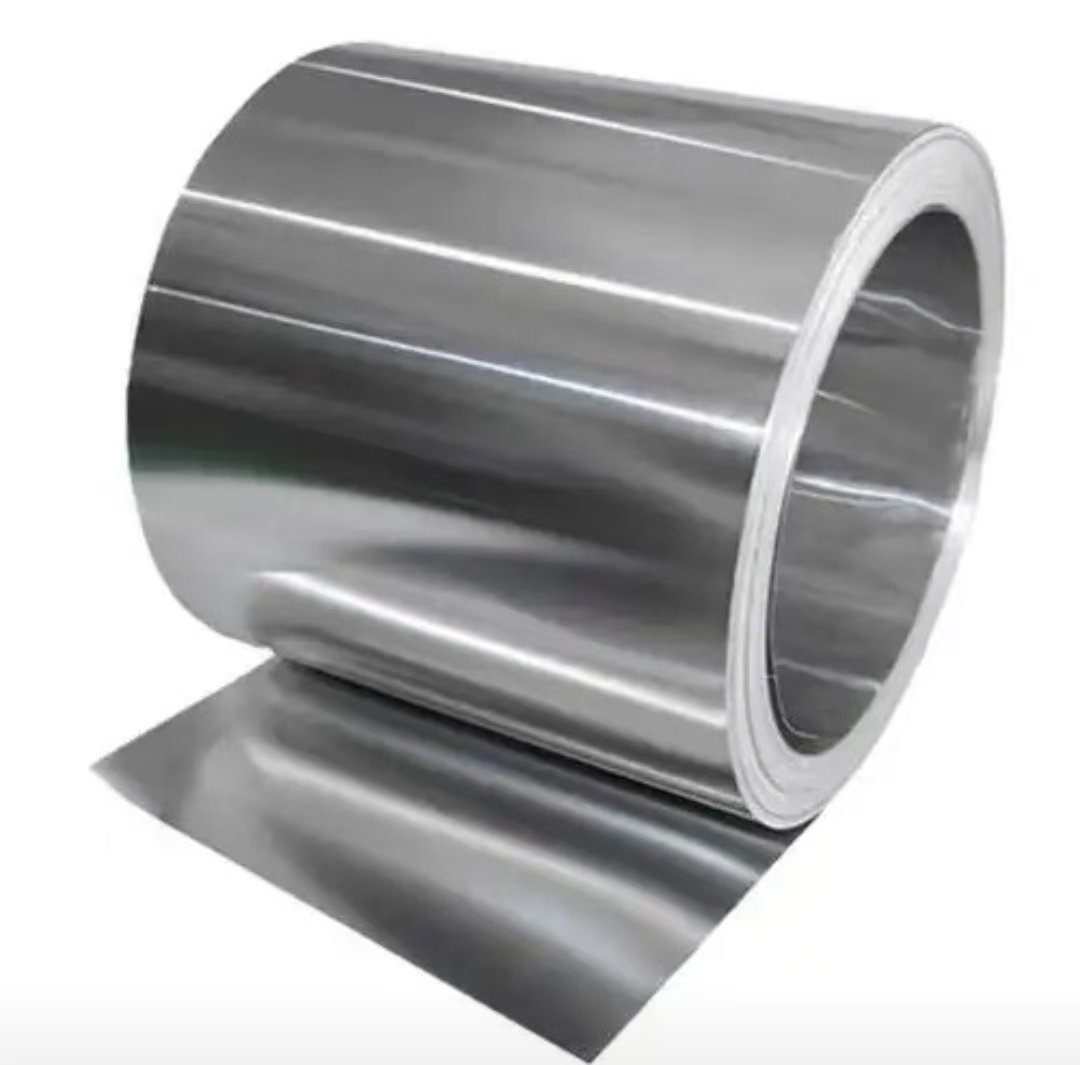

| Nom du produit | Bobine/bande en acier inoxydable |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Matériau | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Technique | Etiré à froid, laminé à chaud, laminé à froid et autres. |

| Largeur | 6-12mm ou personnalisable |

| Épaisseur | 1-12mm ou personnalisable |

| Longueur | 1000 - 6000mm ou personnalisable |

| Traitement de surface | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Origine | Chine |

| Code SH | 7219131200 |

| Délai de livraison | {Délai de livraison} |

| Service après-vente | 24 heures en ligne |

| Capacité de production | {Capacité de production} |

| Conditions de prix | EXW, FOB, CIF, CRF, CNF ou autres. |

| Port de chargement | {Port} |

| Délai de paiement | TT, LC, Cash, Paypal, DP, DA, Western Union ou autres. |

| Application | 1. Vaisselle, armoires, canalisations intérieures, chauffe-eau, chaudières, baignoires |

| 2. Pièces automobiles | |

| 3. équipements médicaux, matériaux de construction, produits chimiques, industrie alimentaire, agriculture, composants de navires, etc. | |

| Emballage | Emballage, sac en PVC, ceinture en nylon, serre-câble, emballage maritime standard pour l'exportation ou selon la demande. |

| Service de traitement | Pliage, soudage, décochage, poinçonnage, découpage et autres. |

| Tolérance | ±1% |

| MOQ | {MOQ} |

Composition de l'acier inoxydable

L'acier est un alliage de fer et de carbone. Les aciers inoxydables sont des aciers contenant au moins 10,5% de chrome, moins de 1,2% de carbone et d'autres éléments d'alliage. La résistance à la corrosion de l'acier inoxydable et

Les propriétés mécaniques peuvent être encore améliorées par l'ajout d'autres éléments, tels que le nickel, le molybdène, le titane, le niobium, le manganèse, etc.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Sélection de la surface