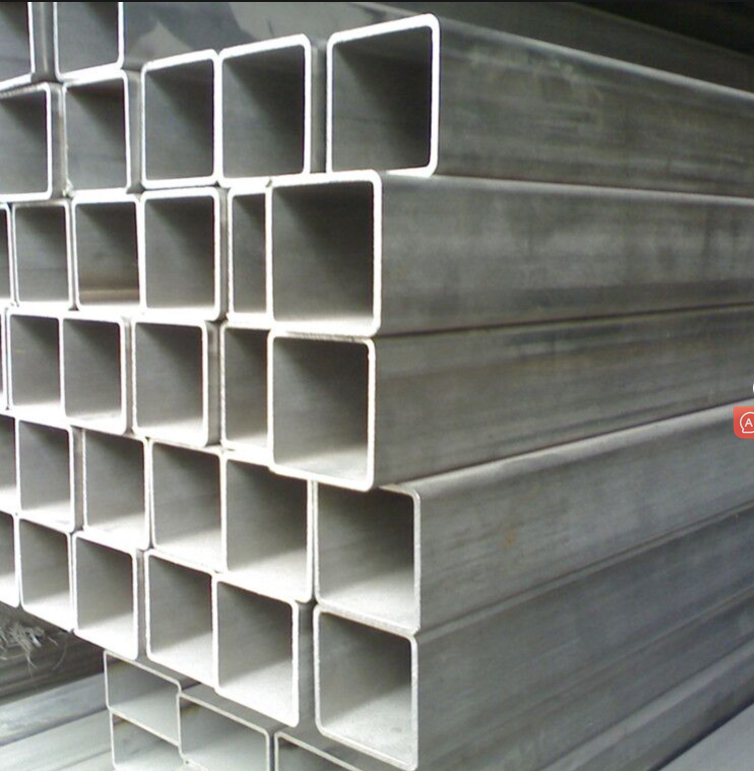

The characteristics of stainless steel square tubes mainly include the following aspects:

Corrosion resistance: Stainless steel square tubes are made of high-quality stainless steel materials and can be used for a long time in various corrosive environments.

High strength: Stainless steel square tubes have good strength and toughness and can withstand certain external loads.

High temperature resistance: Stainless steel square tubes can work in high temperature environments without deformation or oxidation.

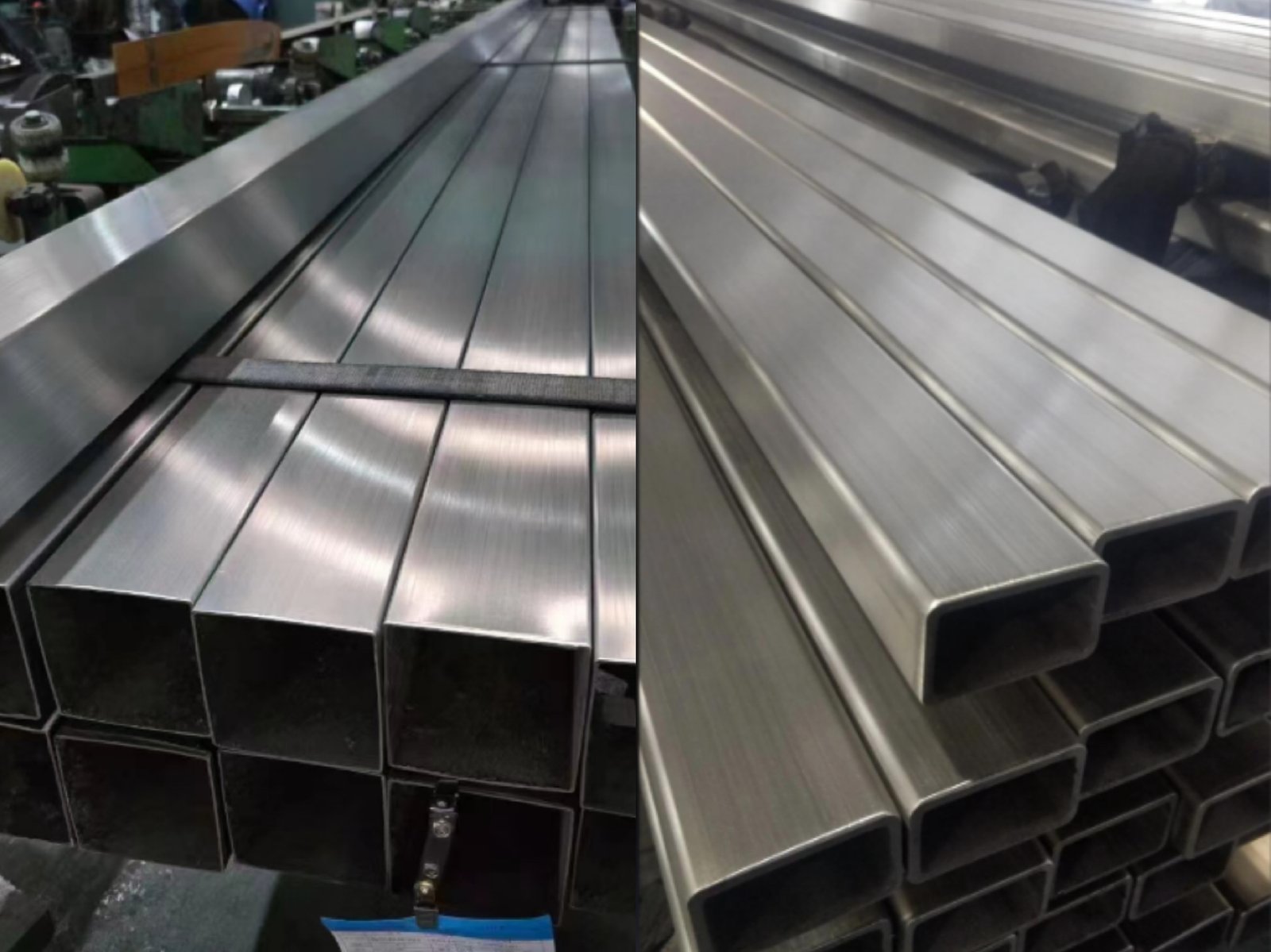

Aesthetics: The surface of stainless steel square tubes is smooth and has no obvious defects, which is suitable for occasions that require a fine appearance.

Easy processing: Stainless steel square tubes have good processability and are easy to cut, weld and install.

Wear resistance: Stainless steel square tubes are not only corrosion-resistant and high-strength, but also wear-resistant and easy to clean. In some occasions that require frequent cleaning and disinfection, equipment, utensils, auxiliary accessories, etc. made of stainless steel square tubes have good cleaning performance, which can effectively prevent the reproduction and spread of microorganisms and meet the requirements of relevant health regulations.

| Product Name | Stainless Steel Pipe/Tube |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Matériau | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Technique | Etiré à froid, laminé à chaud, laminé à froid et autres. |

| Side shape | Round, square, rectangular,etc. |

| Outer Diameter | 20mm-1200mm or Customizable |

| Épaisseur | 6-3000mm or Customizable |

| Longueur | 1-12m or Customizable |

| Traitement de surface | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Type | Seamless, Welded. |

| Origine | Chine |

| Code SH | 7304319000 |

| Délai de livraison | {Délai de livraison} |

| Service après-vente | 24 hours online. |

| Capacité de production | {Capacité de production} |

| Price Terms | EXW, FOB, CIF, CRF, CNF ou autres. |

| Port de chargement | {Port} |

| Section Shape | Round, Square, Rectangular, etc. |

| Délai de paiement | TT, LC, Cash, Paypal, DP, DA, Western Union ou autres. |

| Application | 1. Vaisselle, armoires, canalisations intérieures, chauffe-eau, chaudières, baignoires |

| 2. Pièces automobiles | |

| 3. équipements médicaux, matériaux de construction, produits chimiques, industrie alimentaire, agriculture, composants de navires, etc. | |

| Emballage | Emballage, sac en PVC, ceinture en nylon, serre-câble, emballage maritime standard pour l'exportation ou selon la demande. |

| Service de traitement | Pliage, soudage, décochage, poinçonnage, découpage et autres. |

| Tolérance | ±1% |

| MOQ | {MOQ} |

Composition de l'acier inoxydable

L'acier est un alliage de fer et de carbone. Les aciers inoxydables sont des aciers contenant au moins 10,5% de chrome, moins de 1,2% de carbone et d'autres éléments d'alliage. La résistance à la corrosion de l'acier inoxydable et

Les propriétés mécaniques peuvent être encore améliorées par l'ajout d'autres éléments, tels que le nickel, le molybdène, le titane, le niobium, le manganèse, etc.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |