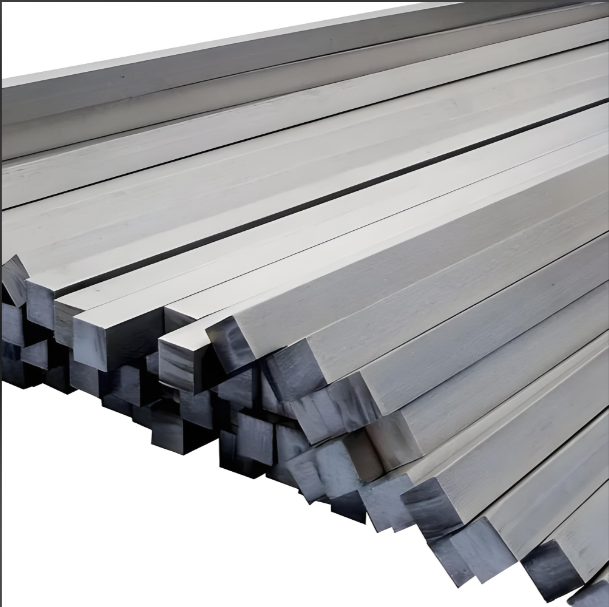

Material and corrosion resistance

Stainless steel square steel is made of 200 series, 300 series or 400 series stainless steel, with a chromium content of at least 10.5%. Some models add elements such as nickel and molybdenum to improve corrosion resistance, especially suitable for humid or chemical corrosion environments.

Mechanical properties

Tensile strength ranges from 310-635MPa, and the temperature range can reach -196℃~800℃. Some models (such as 303, 304F) add sulfur to improve machinability, which is suitable for precision parts processing.

Application scenarios

Widely used in machinery manufacturing, petrochemicals, medical equipment, building bridges and rail transportation, etc., replacing traditional welding with modular connection design to improve assembly efficiency and structural stability.

| Product Name | Barre en acier inoxydable |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Matériau | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Technique | Etiré à froid, laminé à chaud, laminé à froid et autres. |

| Diameter | 6-12mm ou personnalisable |

| Longueur | 1000 – 6000mm or Customizable |

| Traitement de surface | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Origine | Chine |

| Code SH | 7220204000 |

| Délai de livraison | {Délai de livraison} |

| Service après-vente | 24 heures en ligne |

| Capacité de production | {Capacité de production} |

| Conditions de prix | EXW, FOB, CIF, CRF, CNF or others |

| Port de chargement | {Port} |

| Délai de paiement | TT, LC, Cash, Paypal, DP, DA, Western Union or Others. |

| Application | 1. Vaisselle, armoires, canalisations intérieures, chauffe-eau, chaudières, baignoires |

| 2. Pièces automobiles | |

| 3. équipements médicaux, matériaux de construction, produits chimiques, industrie alimentaire, agriculture, composants de navires, etc. | |

| Emballage | Emballage, sac en PVC, ceinture en nylon, serre-câble, emballage maritime standard pour l'exportation ou selon la demande. |

| Service de traitement | Pliage, soudage, décochage, poinçonnage, découpage et autres. |

| Tolérance | ±1% |

| MOQ | {MOQ} |

Composition de l'acier inoxydable

L'acier est un alliage de fer et de carbone. Les aciers inoxydables sont des aciers contenant au moins 10,5% de chrome, moins de 1,2% de carbone et d'autres éléments d'alliage. La résistance à la corrosion de l'acier inoxydable et

Les propriétés mécaniques peuvent être encore améliorées par l'ajout d'autres éléments, tels que le nickel, le molybdène, le titane, le niobium, le manganèse, etc.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |