The main features of SS316L stainless steel coil are as follows:

Chemical composition: The L in SS316L stands for Low Carbon, which means that its carbon content is lower than that of SS316. This low carbon property reduces the risk of intergranular corrosion during welding of SUS316L, thereby improving the welding performance of the material.

Physical properties: The strength and hardness of SS316L are slightly lower than those of SS316, but its plasticity and toughness are relatively good.

Corrosion resistance: The addition of molybdenum to SS316L enhances the repair ability of the passivation film, so it has better corrosion resistance than SS304. Since pitting is difficult to detect from the outside and there is a high risk of sudden damage, SS316L should be selected instead of SS304 in an environment where chlorine is present. For SS316L, there is a concern about intergranular stress corrosion cracking, but SUS316L reduces this risk by reducing carbon.

Application areas: Both SS316L and SS316 are widely used in chemical, medical, marine and other fields. However, according to specific needs and budget, it takes comprehensive consideration to choose which material is more suitable. For example, in the manufacture of thermos cups, if higher corrosion resistance and high temperature performance are sought, SS316 may be a better choice; if a more economical material is needed while meeting basic corrosion resistance and high temperature resistance requirements, then SS316L is more suitable.

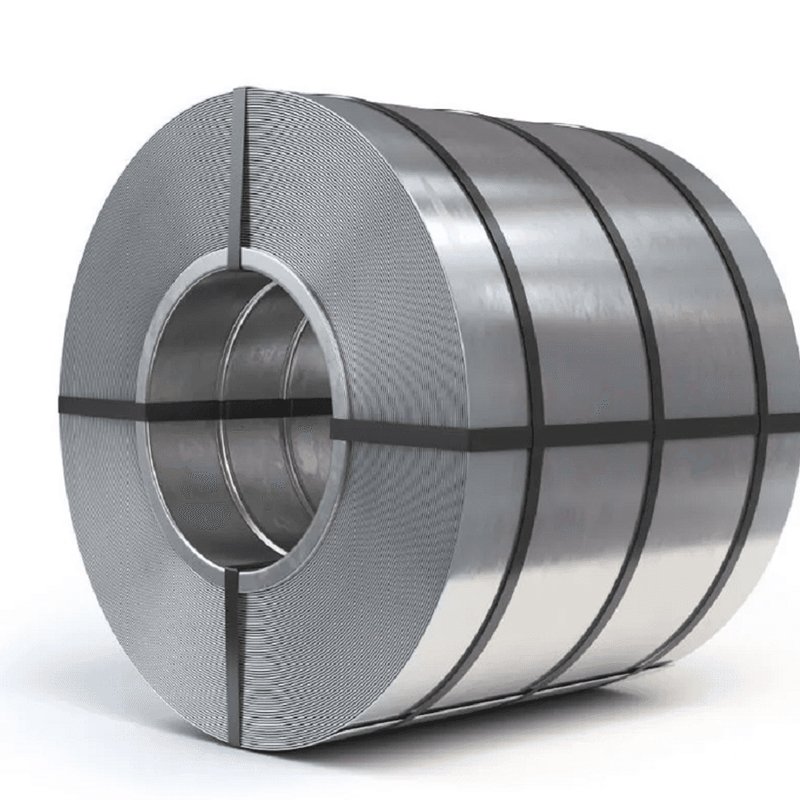

| Nombre del producto | Bobina/tira de acero inoxidable |

| Estándar | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Técnica | Estirado en frío, Laminado en caliente, Laminado en frío y Otros. |

| Anchura | 6-12 mm o personalizable |

| Espesor | 1-12 mm o personalizable |

| Longitud | 1000 - 6000 mm o personalizable |

| Tratamiento de superficies | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Origen | China |

| Código SA | 7219131200 |

| Plazo de entrega | {Tiempo de entrega} |

| Servicio posventa | 24 horas en línea |

| Capacidad de producción | {Capacidad de producción} |

| Condiciones de precio | EXW, FOB, CIF, CRF, CNF u otros. |

| Puerto de carga | {Puerto} |

| Plazo de pago | TT, LC,Efectivo, Paypal, DP, DA,Western Union u Otros. |

| Aplicación | 1. Vajilla, armarios, tuberías interiores, calentadores de agua, calderas, bañeras |

| 2. Piezas de automóvil | |

| 3. Equipamiento médico, materiales de construcción, productos químicos, industria alimentaria, agricultura, componentes navales, etc. | |

| Embalaje | Paquete, bolsa de PVC, cinturón de nylon, atadura de cables, paquete marítimo de exportación estándar o como petición. |

| Servicio de tramitación | Doblado, soldadura, desbobinado, punzonado, corte y otros. |

| Tolerancia | ±1% |

| MOQ | {MOQ} |

Composición del acero inoxidable

El acero es una aleación de hierro y carbono. Los aceros inoxidables son aceros que contienen al menos 10,5% de cromo, menos de 1,2% de carbono y otros elementos de aleación. La resistencia a la corrosión del acero inoxidable y

Las propiedades mecánicas pueden mejorarse aún más añadiendo otros elementos, como níquel, molibdeno, titanio, niobio, manganeso, etc.

| Grado | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Selección de superficies