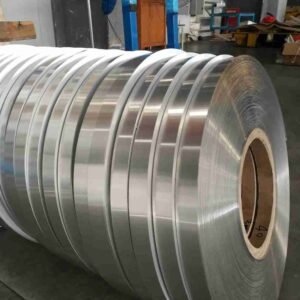

The characteristics of SS 304 stainless steel strip are as follows:

Corrosion resistance: 304 stainless steel strip has excellent stainless corrosion resistance and good intergranular corrosion resistance. It has strong corrosion resistance to oxidizing acids, such as nitric acid below boiling temperature with a concentration of ≤65%. At the same time, it also has good corrosion resistance to alkaline solutions and most organic and inorganic acids4.

Physical and chemical properties: 304 stainless steel strip has good corrosion resistance, heat resistance, low temperature strength and mechanical properties. It has good hot processing properties such as stamping/bending, no heat treatment hardening phenomenon (non-magnetic), and the operating temperature range is -196℃ to 800℃2.

Processing performance: 304 stainless steel strip has good processing performance, can be stamped, bent and other hot processing, and will not have heat treatment hardening phenomenon. It can be processed into products of various shapes to meet the needs of different shapes and sizes1.

Application areas: 304 stainless steel strips are widely used in household goods, auto parts, medical equipment, building materials, chemical industry, food industry, agriculture, ship parts, etc.

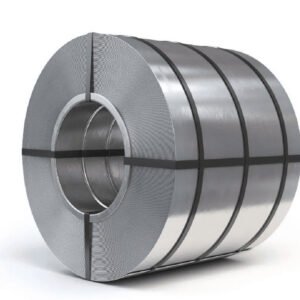

| Nombre del producto | Bobina/tira de acero inoxidable |

| Estándar | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Técnica | Estirado en frío, Laminado en caliente, Laminado en frío y Otros. |

| Anchura | 6-12 mm o personalizable |

| Espesor | 1-12 mm o personalizable |

| Longitud | 1000 - 6000 mm o personalizable |

| Tratamiento de superficies | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Origen | China |

| Código SA | 7219131200 |

| Plazo de entrega | {Tiempo de entrega} |

| Servicio posventa | 24 horas en línea |

| Capacidad de producción | {Capacidad de producción} |

| Condiciones de precio | EXW, FOB, CIF, CRF, CNF u otros. |

| Puerto de carga | {Puerto} |

| Plazo de pago | TT, LC,Efectivo, Paypal, DP, DA,Western Union u Otros. |

| Aplicación | 1. Vajilla, armarios, tuberías interiores, calentadores de agua, calderas, bañeras |

| 2. Piezas de automóvil | |

| 3. Equipamiento médico, materiales de construcción, productos químicos, industria alimentaria, agricultura, componentes navales, etc. | |

| Embalaje | Paquete, bolsa de PVC, cinturón de nylon, atadura de cables, paquete marítimo de exportación estándar o como petición. |

| Servicio de tramitación | Doblado, soldadura, desbobinado, punzonado, corte y otros. |

| Tolerancia | ±1% |

| MOQ | {MOQ} |

Composición del acero inoxidable

El acero es una aleación de hierro y carbono. Los aceros inoxidables son aceros que contienen al menos 10,5% de cromo, menos de 1,2% de carbono y otros elementos de aleación. La resistencia a la corrosión del acero inoxidable y

Las propiedades mecánicas pueden mejorarse aún más añadiendo otros elementos, como níquel, molibdeno, titanio, niobio, manganeso, etc.

| Grado | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Selección de superficies