SS410 stainless steel (AISI 410) is a martensitic stainless steel with the following characteristics:

Chemical composition and corrosion resistance

The chromium content is about 12% (11.5-13.5%), with medium corrosion resistance, suitable for fresh water, weak acid and other environments, but poor corrosion resistance to strong oxidizing media such as nitric acid and concentrated sulfuric acid.

Mechanical properties

Tensile strength 60-75 ksi, yield strength 32-42 ksi, elongation 20-40%, hardness can be increased to Rc 35 or above by heat treatment, suitable for high strength demand scenarios.

Application scenarios

Commonly used in steam turbines, gas turbines, valves, fasteners and other parts that require heat resistance and wear resistance, not suitable for high temperature (>1200°F) or highly corrosive environments.

Processing characteristics

Forging requires uniform heating to above 900℃, welding requires preheating to 180-205℃, and mechanical properties are significantly improved after heat treatment.

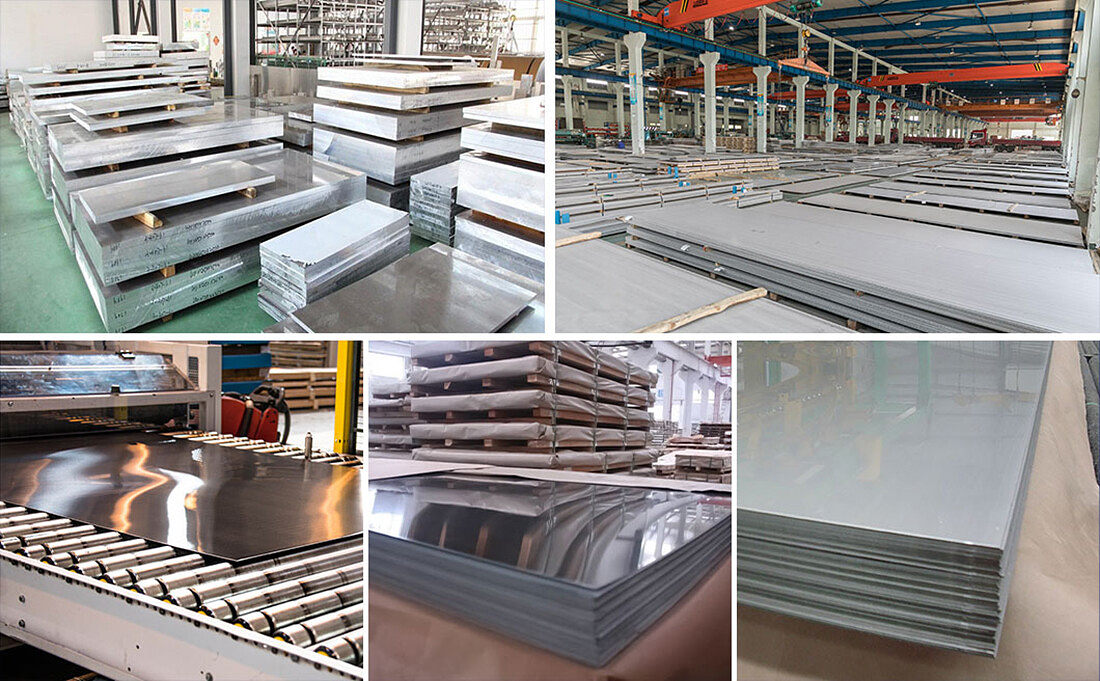

| Product Name | Stainless Steel Plate/Sheet |

| Estándar | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Técnica | Estirado en frío, Laminado en caliente, Laminado en frío y Otros. |

| Anchura | 6-12 mm o personalizable |

| Espesor | 1-120mm or Customizable |

| Longitud | 1000 – 6000mm or Customizable |

| Tratamiento de superficies | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Origen | China |

| Código SA | 7211190000 |

| Plazo de entrega | {Tiempo de entrega} |

| Servicio posventa | 24 horas en línea |

| Capacidad de producción | {Capacidad de producción} |

| Condiciones de precio | EXW, FOB, CIF, CRF, CNF or Others |

| Puerto de carga | {Puerto} |

| Plazo de pago | TT, LC,Efectivo, Paypal, DP, DA,Western Union u Otros. |

| Aplicación | 1. Architectural decoration. Such as exterior walls, curtain walls, ceilings, stair handrails, doors and windows, etc. |

| 2. Kitchen furniture. Such as kitchen stove, sink, etc. | |

| 3. Chemical equipment. Such as containers, pipelines, etc. | |

| 4. Food processing. Such as food containers, processing tables, etc. | |

| 5. Automobile manufacturing. Such as vehicle body, exhaust pipe, fuel tank, etc. | |

| 6. Electronic devices. Such as manufacturing casings, structural components, etc. for electronic devices. | |

| 7. Medical equipment. Such as surgical instruments, surgical instruments, medical utensils, etc. | |

| 8. Shipbuilding. Such as ship hulls, pipelines, equipment supports, etc. | |

| Embalaje | Paquete, bolsa de PVC, cinturón de nylon, atadura de cables, paquete marítimo de exportación estándar o como petición. |

| Servicio de tramitación | Doblado, soldadura, desbobinado, punzonado, corte y otros. |

| Tolerancia | ±1% |

| MOQ | {MOQ} |

Composición del acero inoxidable

El acero es una aleación de hierro y carbono. Los aceros inoxidables son aceros que contienen al menos 10,5% de cromo, menos de 1,2% de carbono y otros elementos de aleación. La resistencia a la corrosión del acero inoxidable y

Las propiedades mecánicas pueden mejorarse aún más añadiendo otros elementos, como níquel, molibdeno, titanio, niobio, manganeso, etc.

| Grado | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Selección de superficies