Corrosion resistance

TP304 is an austenitic stainless steel containing 18%-20% chromium and 8%-11% nickel. It exhibits excellent corrosion resistance in oxidizing environments, especially for common acid and alkali media such as dilute sulfuric acid and dilute nitric acid. Its intergranular corrosion resistance is comparable to that of Super304H, but σ phase and carbide precipitation may occur after high-temperature aging, resulting in a decrease in thermal strength.

Mechanical properties

High temperature performance: Long-term use temperature can reach 650℃, and oxidation resistance temperature can reach 850℃.

Processing performance: Excellent cold deformation ability, supporting bending, cutting and sizing processing.

Mechanical properties: Tensile strength, yield strength and elongation all meet industry standards, and the elongation can reach more than 35% after heat treatment.

Application scenarios

Chemical/petroleum: Used in heat exchangers, pipelines and other equipment, corrosion-resistant and pressure-resistant.

Food processing: The surface is smooth and easy to clean, suitable for food pipelines such as dairy products and meat processing.

Medical equipment: manufacturing surgical instruments, implant housings and piping systems with good biocompatibility.

Architectural decoration: used for high-end building handrails, door and window frames, etc., with both corrosion resistance and aesthetics.

Production process

The organization properties are optimized through hot rolling perforation, cold rolling forming and solution heat treatment, and the specifications cover pipes with an outer diameter of 6-377mm and a wall thickness of 1.0-20mm.

| Product Name | Tubos de acero inoxidable |

| Estándar | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Técnica | Estirado en frío, Laminado en caliente, Laminado en frío y Otros. |

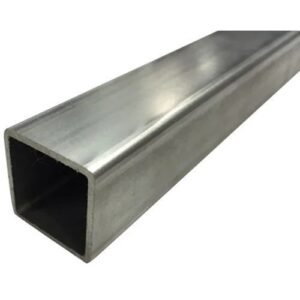

| Side shape | Round, square, rectangular,etc. |

| Outer Diameter | 20mm-1200mm or Customizable |

| Espesor | 6-3000mm or Customizable |

| Longitud | 1-12m or Customizable |

| Tratamiento de superficies | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Tipo | Seamless, Welded. |

| Origen | China |

| Código SA | 7304319000 |

| Plazo de entrega | {Tiempo de entrega} |

| Servicio posventa | 24 hours online. |

| Capacidad de producción | {Capacidad de producción} |

| Price Terms | EXW, FOB, CIF, CRF, CNF u otros. |

| Puerto de carga | {Puerto} |

| Section Shape | Round, Square, Rectangular, etc. |

| Plazo de pago | TT, LC,Efectivo, Paypal, DP, DA,Western Union u Otros. |

| Aplicación | 1. Vajilla, armarios, tuberías interiores, calentadores de agua, calderas, bañeras |

| 2. Piezas de automóvil | |

| 3. Equipamiento médico, materiales de construcción, productos químicos, industria alimentaria, agricultura, componentes navales, etc. | |

| Embalaje | Paquete, bolsa de PVC, cinturón de nylon, atadura de cables, paquete marítimo de exportación estándar o como petición. |

| Servicio de tramitación | Doblado, soldadura, desbobinado, punzonado, corte y otros. |

| Tolerancia | ±1% |

| MOQ | {MOQ} |

Composición del acero inoxidable

El acero es una aleación de hierro y carbono. Los aceros inoxidables son aceros que contienen al menos 10,5% de cromo, menos de 1,2% de carbono y otros elementos de aleación. La resistencia a la corrosión del acero inoxidable y

Las propiedades mecánicas pueden mejorarse aún más añadiendo otros elementos, como níquel, molibdeno, titanio, niobio, manganeso, etc.

| Grado | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |