Stainless steel seamless pipes are suitable materials for various applications. They are highly durable and can resist corrosion and other elements that can damage other materials. They also have many other benefits, including cost-savings, ease of installation and maintenance, and versatility.

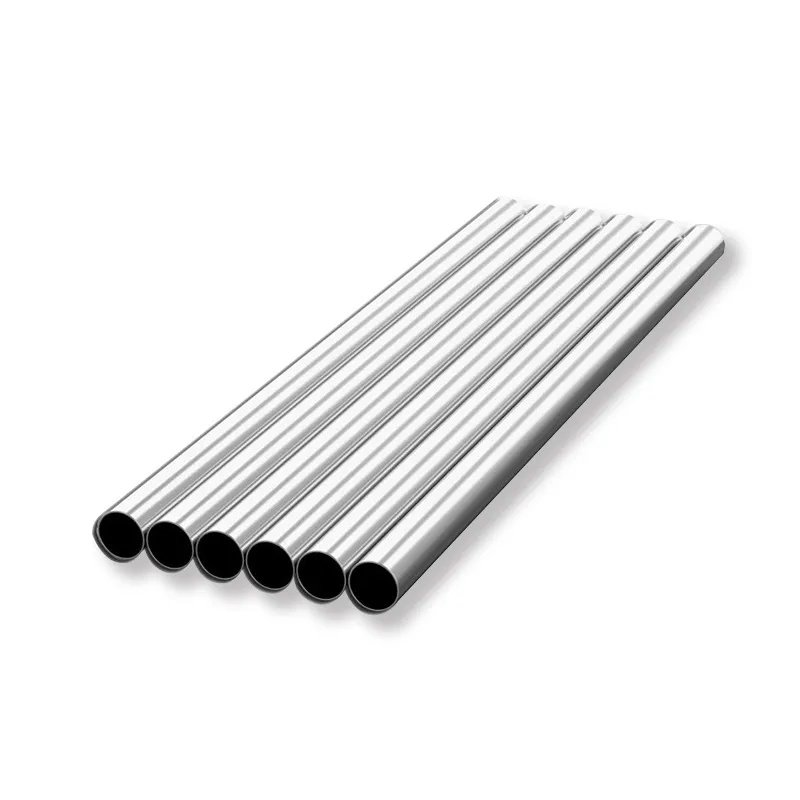

About Stainless Steel Seamless Pipes

Stainless Steel 310 Seamless Pipes are long strips of steel with a hollow section. They have high corrosion resistance, good strength, and a smooth surface. Also, they are used for fluid transport projects in various industries. These pipes are available in multiple materials, sizes, and alloys. Stainless Steel 310 Seamless Pipes are manufactured to ASTM and API standards specifications. Also, the wall thicknesses are based on schedules. These specifications are also used for welded stainless steel tubes. The pipe has a variety of applications, including thermal and solar, as well as petrochemical. The seamless pipe has a higher cost because of the manufacturing process and materials. Moreover, the thinner the wall thickness, the more expensive it is. The forming process requires expensive equipment.

Properties :

Stainless steel seamless pipes are used in a wide variety of applications. They are used for various industrial purposes, including water treatment, gas, oil and chemical industries. Also, they resist corrosive attacks and are not affected by aggressive chemicals. They are also high-performance and heat-resistant. Stainless steel seamless pipes are available in various grades, which vary in their properties. They are classified into three categories: ferritic, austenitic and martensite. Alloys with chromium are also available. These provide corrosion resistance and increase the surface layer of the pipe. 310 grade is the most widely used of these pipes. It has excellent corrosion resistance and can withstand high temperatures in cryogenic environments. It is a cost-effective product. Also, it is primarily utilized in structural applications. It has good work ability and welding properties. The chemical composition of grade 310 is similar to that of the austenitic and martensite grades. It has improved strength, flexibility and corrosion resistance.

Benefits:

Stainless steel seamless pipes are a type of pipe that is made without any joints. This type of pipe is versatile and can be used in several applications. It is known for its high resistance to corrosion and oxidation. It is an excellent material for use in engineering and mechanical industries. It can be formed and manufactured easily. It can withstand very high pressure. It can withstand temperatures of up to 1100 degrees Celsius. Also, its rust resistance makes it perfect for use in extreme environments. It is lightweight, which makes it a favourite for many applications. The chromium content of stainless steel improves its corrosion resistance. It also adds to its strength and formability. The chromium (III) oxide forms a protective layer over the surface of the alloy. This process prevents the iron from oxidizing.

Applications:

Stainless steel seamless pipes are used in a wide variety of industries. They are often used in oil and gas production and offer excellent corrosion resistance. They are also popular in medical devices. Some of the most common stainless steel applications are in the chemical industry. They can withstand high temperatures and have good corrosion resistance. They have a long life cycle and a low maintenance rate. Stainless steel is also used for the manufacture of heat exchangers. It is also used in the transportation of hot and cold liquids. It is a lightweight material. It is used in a variety of industries, including medical and aerospace. The higher the chromium content, the stronger the material will be. This composition makes it ideal for piping systems.

| Product Name | Tubos de acero inoxidable |

| Estándar | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Técnica | Estirado en frío, Laminado en caliente, Laminado en frío y Otros. |

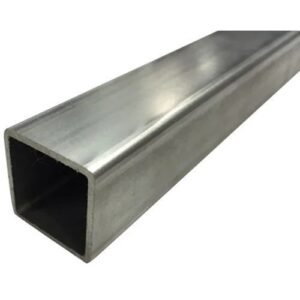

| Side shape | Round, square, rectangular,etc. |

| Outer Diameter | 20mm-1200mm or Customizable |

| Espesor | 6-3000mm or Customizable |

| Longitud | 1-12m or Customizable |

| Tratamiento de superficies | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Tipo | Seamless, Welded. |

| Origen | China |

| Código SA | 7304319000 |

| Plazo de entrega | {Tiempo de entrega} |

| Servicio posventa | 24 hours online. |

| Capacidad de producción | {Capacidad de producción} |

| Price Terms | EXW, FOB, CIF, CRF, CNF u otros. |

| Puerto de carga | {Puerto} |

| Section Shape | Round, Square, Rectangular, etc. |

| Plazo de pago | TT, LC,Efectivo, Paypal, DP, DA,Western Union u Otros. |

| Aplicación | 1. Vajilla, armarios, tuberías interiores, calentadores de agua, calderas, bañeras |

| 2. Piezas de automóvil | |

| 3. Equipamiento médico, materiales de construcción, productos químicos, industria alimentaria, agricultura, componentes navales, etc. | |

| Embalaje | Paquete, bolsa de PVC, cinturón de nylon, atadura de cables, paquete marítimo de exportación estándar o como petición. |

| Servicio de tramitación | Doblado, soldadura, desbobinado, punzonado, corte y otros. |

| Tolerancia | ±1% |

| MOQ | {MOQ} |

Composición del acero inoxidable

El acero es una aleación de hierro y carbono. Los aceros inoxidables son aceros que contienen al menos 10,5% de cromo, menos de 1,2% de carbono y otros elementos de aleación. La resistencia a la corrosión del acero inoxidable y

Las propiedades mecánicas pueden mejorarse aún más añadiendo otros elementos, como níquel, molibdeno, titanio, niobio, manganeso, etc.

| Grado | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |