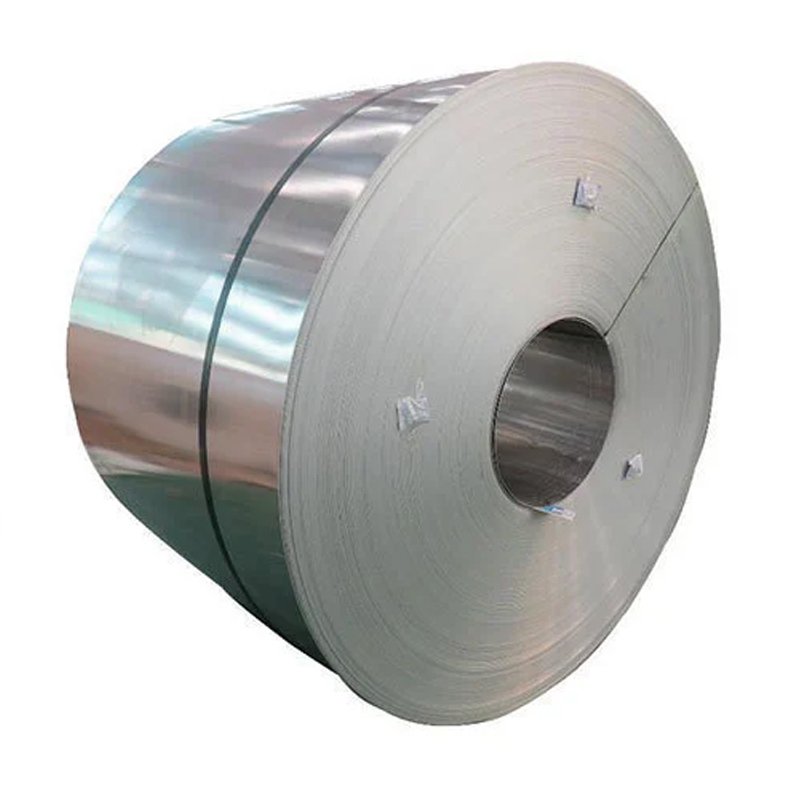

The main features of SS 201 stainless steel strip are as follows:

Material characteristics: SS 201 stainless steel is a chromium-manganese austenitic stainless steel, containing a large amount of manganese, as well as a certain amount of chromium, carbon and other small amounts of elements. It has certain acid and alkali resistance, high density, no bubbles, no pinholes after polishing, etc.1.

Performance characteristics: The hot and cold processing performance and welding performance of SS 201 stainless steel strip are relatively poor, and the sensitivity to hot cracks is strong. It has high strength and is suitable for applications such as stainless steel straps, clips, brackets and cable ties41.

Price factors: Due to the low nickel content in SS 201 stainless steel, its price is usually about half that of 304 stainless steel.

| Produktname | Edelstahl Spule/Band |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Technik | Kaltgezogen, warmgewalzt, kaltgewalzt und andere. |

| Breite | 6-12mm oder anpassbar |

| Dicke | 1-12mm oder anpassbar |

| Länge | 1000 - 6000mm oder anpassbar |

| Oberflächenbehandlung | BA/2B/NR.1/NR.3/NR.4/8K/HL/2D/1D |

| Herkunft | China |

| HS-Code | 7219131200 |

| Lieferfrist | {Lieferzeit} |

| Service nach dem Verkauf | 24 Stunden online |

| Produktionskapazität | {Produktionskapazität} |

| Preis Konditionen | EXW, FOB, CIF, CRF, CNF oder andere. |

| Hafen laden | {Port} |

| Zahlungsfrist | TT, LC, Bargeld, Paypal, DP, DA, Western Union oder andere. |

| Anmeldung | 1. Geschirr, Schränke, Rohrleitungen in Innenräumen, Warmwasserbereiter, Boiler, Badewannen |

| 2. Automobilteile | |

| 3. medizinische Geräte, Baumaterialien, Chemikalien, Lebensmittelindustrie, Landwirtschaft, Schiffskomponenten, usw. | |

| Verpackung | Bündel, PVC-Beutel, Nylongürtel, Kabelbinder, Standard-Export seetüchtig Paket oder als Anfrage. |

| Bearbeitungsservice | Biegen, Schweißen, Abwickeln, Stanzen, Schneiden und andere. |

| Toleranz | ±1% |

| MOQ | {MOQ} |

Zusammensetzung von rostfreiem Stahl

Stahl ist eine Legierung aus Eisen und Kohlenstoff. Nichtrostende Stähle sind Stähle mit mindestens 10,5% Chrom, weniger als 1,2% Kohlenstoff und anderen Legierungselementen. Die Korrosionsbeständigkeit von rostfreiem Stahl und

Die mechanischen Eigenschaften können durch Zugabe anderer Elemente wie Nickel, Molybdän, Titan, Niob, Mangan usw. weiter verbessert werden.

| Klasse | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Auswahl der Oberfläche