The main features of SS316L stainless steel coil are as follows:

Chemical composition: The L in SS316L stands for Low Carbon, which means that its carbon content is lower than that of SS316. This low carbon property reduces the risk of intergranular corrosion during welding of SUS316L, thereby improving the welding performance of the material.

Physical properties: The strength and hardness of SS316L are slightly lower than those of SS316, but its plasticity and toughness are relatively good.

Corrosion resistance: The addition of molybdenum to SS316L enhances the repair ability of the passivation film, so it has better corrosion resistance than SS304. Since pitting is difficult to detect from the outside and there is a high risk of sudden damage, SS316L should be selected instead of SS304 in an environment where chlorine is present. For SS316L, there is a concern about intergranular stress corrosion cracking, but SUS316L reduces this risk by reducing carbon.

Application areas: Both SS316L and SS316 are widely used in chemical, medical, marine and other fields. However, according to specific needs and budget, it takes comprehensive consideration to choose which material is more suitable. For example, in the manufacture of thermos cups, if higher corrosion resistance and high temperature performance are sought, SS316 may be a better choice; if a more economical material is needed while meeting basic corrosion resistance and high temperature resistance requirements, then SS316L is more suitable.

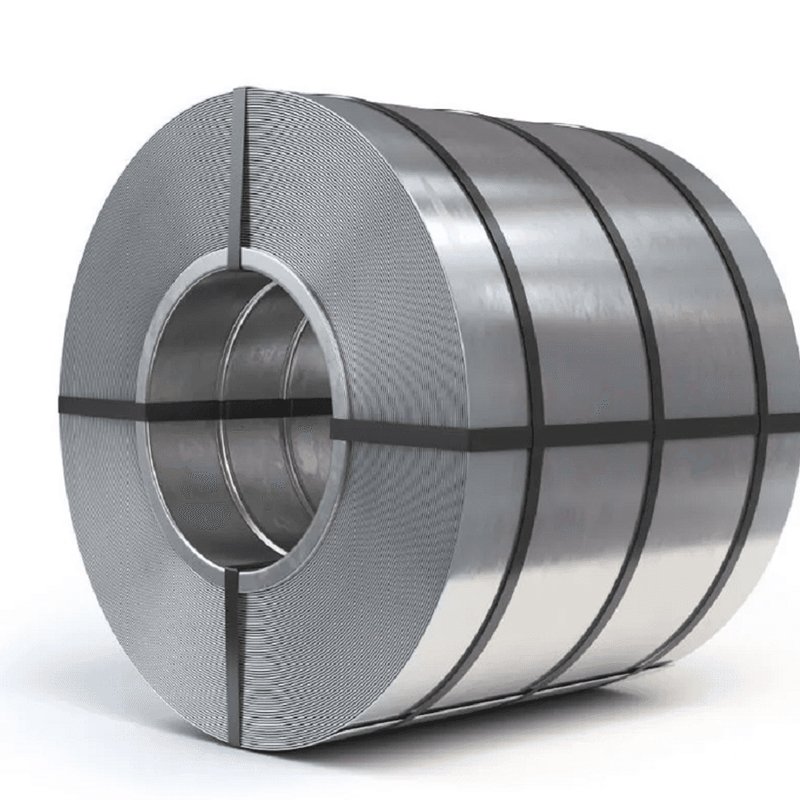

| Produktname | Edelstahl Spule/Band |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Technik | Kaltgezogen, warmgewalzt, kaltgewalzt und andere. |

| Breite | 6-12mm oder anpassbar |

| Dicke | 1-12mm oder anpassbar |

| Länge | 1000 - 6000mm oder anpassbar |

| Oberflächenbehandlung | BA/2B/NR.1/NR.3/NR.4/8K/HL/2D/1D |

| Herkunft | China |

| HS-Code | 7219131200 |

| Lieferfrist | {Lieferzeit} |

| Service nach dem Verkauf | 24 Stunden online |

| Produktionskapazität | {Produktionskapazität} |

| Preis Konditionen | EXW, FOB, CIF, CRF, CNF oder andere. |

| Hafen laden | {Port} |

| Zahlungsfrist | TT, LC, Bargeld, Paypal, DP, DA, Western Union oder andere. |

| Anmeldung | 1. Geschirr, Schränke, Rohrleitungen in Innenräumen, Warmwasserbereiter, Boiler, Badewannen |

| 2. Automobilteile | |

| 3. medizinische Geräte, Baumaterialien, Chemikalien, Lebensmittelindustrie, Landwirtschaft, Schiffskomponenten, usw. | |

| Verpackung | Bündel, PVC-Beutel, Nylongürtel, Kabelbinder, Standard-Export seetüchtig Paket oder als Anfrage. |

| Bearbeitungsservice | Biegen, Schweißen, Abwickeln, Stanzen, Schneiden und andere. |

| Toleranz | ±1% |

| MOQ | {MOQ} |

Zusammensetzung von rostfreiem Stahl

Stahl ist eine Legierung aus Eisen und Kohlenstoff. Nichtrostende Stähle sind Stähle mit mindestens 10,5% Chrom, weniger als 1,2% Kohlenstoff und anderen Legierungselementen. Die Korrosionsbeständigkeit von rostfreiem Stahl und

Die mechanischen Eigenschaften können durch Zugabe anderer Elemente wie Nickel, Molybdän, Titan, Niob, Mangan usw. weiter verbessert werden.

| Klasse | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Auswahl der Oberfläche