The main features of SS321 stainless steel strip are as follows:

Corrosion resistance: 321 stainless steel strip has good corrosion resistance and can resist the erosion of most organic and inorganic acids.

High temperature strength: Due to the addition of titanium, 321 stainless steel strip can still maintain high strength and hardness at high temperatures, and is suitable for manufacturing parts used under high temperature corrosion conditions of 400-900 degrees.

Anti-oxidation performance: 321 stainless steel strip has excellent anti-oxidation performance, which enables it to maintain stable performance even in high temperature environments.

Welding performance: 321 stainless steel strip has good welding performance, which is convenient for welding operations during the manufacturing process and improves production efficiency.

Machinability: Despite its high strength, 321 stainless steel strip still maintains good machinability and is easy to perform cold processing and forging.

Radiation damage resistance: In the fields of nuclear fuel processing, nuclear waste processing, etc., 321 stainless steel strip shows good radiation damage resistance.

Surface finish: The surface finish of 321 stainless steel strip is high and can be polished to improve the appearance quality of the product

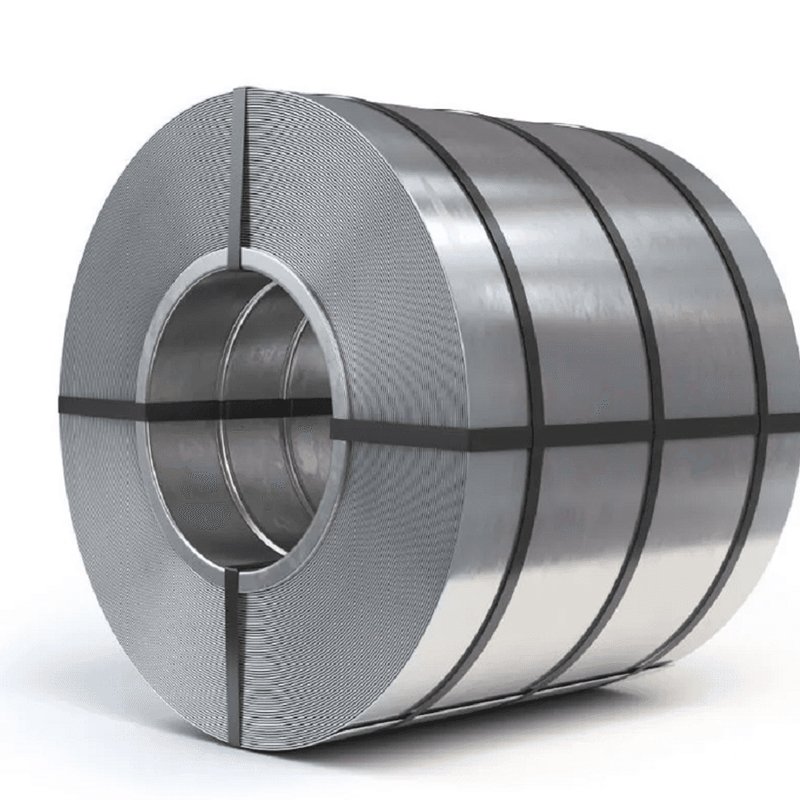

| Produktname | Edelstahl Spule/Band |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Technik | Kaltgezogen, warmgewalzt, kaltgewalzt und andere. |

| Breite | 6-12mm oder anpassbar |

| Dicke | 1-12mm oder anpassbar |

| Länge | 1000 - 6000mm oder anpassbar |

| Oberflächenbehandlung | BA/2B/NR.1/NR.3/NR.4/8K/HL/2D/1D |

| Herkunft | China |

| HS-Code | 7219131200 |

| Lieferfrist | {Lieferzeit} |

| Service nach dem Verkauf | 24 Stunden online |

| Produktionskapazität | {Produktionskapazität} |

| Preis Konditionen | EXW, FOB, CIF, CRF, CNF oder andere. |

| Hafen laden | {Port} |

| Zahlungsfrist | TT, LC, Bargeld, Paypal, DP, DA, Western Union oder andere. |

| Anmeldung | 1. Geschirr, Schränke, Rohrleitungen in Innenräumen, Warmwasserbereiter, Boiler, Badewannen |

| 2. Automobilteile | |

| 3. medizinische Geräte, Baumaterialien, Chemikalien, Lebensmittelindustrie, Landwirtschaft, Schiffskomponenten, usw. | |

| Verpackung | Bündel, PVC-Beutel, Nylongürtel, Kabelbinder, Standard-Export seetüchtig Paket oder als Anfrage. |

| Bearbeitungsservice | Biegen, Schweißen, Abwickeln, Stanzen, Schneiden und andere. |

| Toleranz | ±1% |

| MOQ | {MOQ} |

Zusammensetzung von rostfreiem Stahl

Stahl ist eine Legierung aus Eisen und Kohlenstoff. Nichtrostende Stähle sind Stähle mit mindestens 10,5% Chrom, weniger als 1,2% Kohlenstoff und anderen Legierungselementen. Die Korrosionsbeständigkeit von rostfreiem Stahl und

Die mechanischen Eigenschaften können durch Zugabe anderer Elemente wie Nickel, Molybdän, Titan, Niob, Mangan usw. weiter verbessert werden.

| Klasse | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

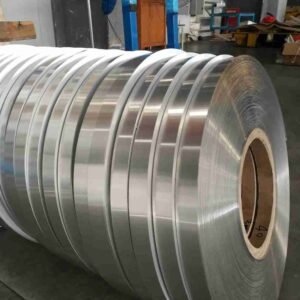

Auswahl der Oberfläche