SS409 stainless steel (ferritic stainless steel) has the following characteristics:

Korrosionsbeständigkeit

It has good resistance to most corrosive media such as acids, alkalis, and salts at room temperature, and remains stable in high temperature environments. However, it should be used with caution in chlorine-containing environments.

High temperature performance

It can withstand repeated heating below 980°C, and still maintain strength and toughness at high temperatures (about 1370-1400°C), which is suitable for high-temperature scenes such as exhaust systems and burners.

Processing performance

It is easy to cut, weld and form. During processing, attention should be paid to cleanliness to avoid contamination. The risk of carbide precipitation during welding is low, which is suitable for complex structure manufacturing.

Mechanische Eigenschaften

Tensile strength is about 490 MPa, yield strength ≥900 MPa, elongation ≥15%, and it has both strength and plasticity.

Cost and applicability

The cost is lower than that of 300 series stainless steel. It is widely used in scenes such as automotive exhaust systems, building decoration, and chemical equipment, but the surface is easily scratched.

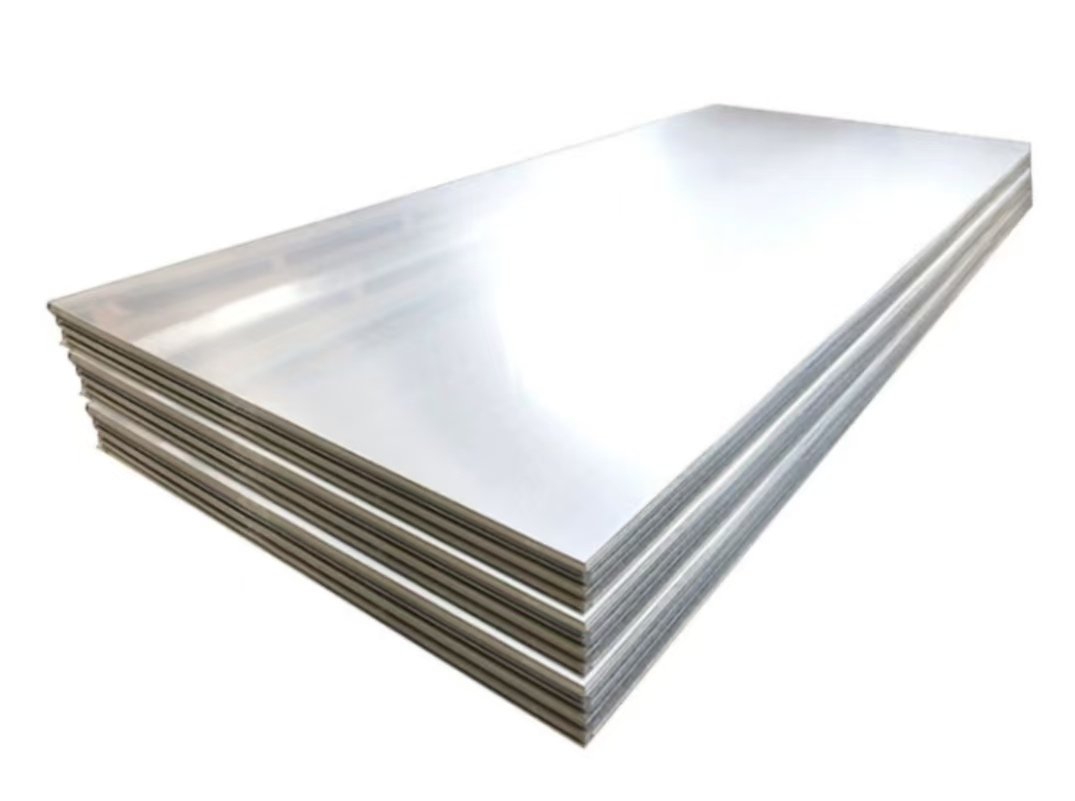

| Produktname | Platte/Blech aus nichtrostendem Stahl |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Material | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H, 347, 347H, 403, 405, 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Technik | Kaltgezogen, warmgewalzt, kaltgewalzt und andere. |

| Breite | 6-12mm oder anpassbar |

| Dicke | 1-120mm oder anpassbar |

| Länge | 1000 - 6000mm oder anpassbar |

| Oberflächenbehandlung | BA/2B/NR.1/NR.3/NR.4/8K/HL/2D/1D |

| Herkunft | China |

| HS-Code | 7211190000 |

| Lieferfrist | {Lieferzeit} |

| Service nach dem Verkauf | 24 Stunden online |

| Produktionskapazität | {Produktionskapazität} |

| Preis Konditionen | EXW, FOB, CIF, CRF, CNF oder andere |

| Hafen laden | {Port} |

| Zahlungsfrist | TT, LC, Bargeld, Paypal, DP, DA, Western Union oder andere. |

| Anmeldung | 1. Architektonische Dekoration. Wie Außenwände, Vorhangfassaden, Decken, Treppengeländer, Türen und Fenster usw. |

| 2. Küchenmöbel. Wie Küchenherd, Spüle, etc. | |

| 3. Chemische Ausrüstung. Wie z. B. Behälter, Pipelines usw. | |

| 4. Lebensmittelverarbeitung. Wie z.B. Lebensmittelbehälter, Verarbeitungstische, etc. | |

| 5. Herstellung von Kraftfahrzeugen. Wie z. B. Fahrzeugkarosserie, Auspuff, Kraftstofftank usw. | |

| 6. Elektronische Geräte. Zum Beispiel die Herstellung von Gehäusen, Bauteilen usw. für elektronische Geräte. | |

| 7. Medizinische Ausrüstung. Wie z.B. chirurgische Instrumente, chirurgische Instrumente, medizinische Utensilien, etc. | |

| 8. Schiffbau. Wie Schiffsrümpfe, Rohrleitungen, Ausrüstungsträger usw. | |

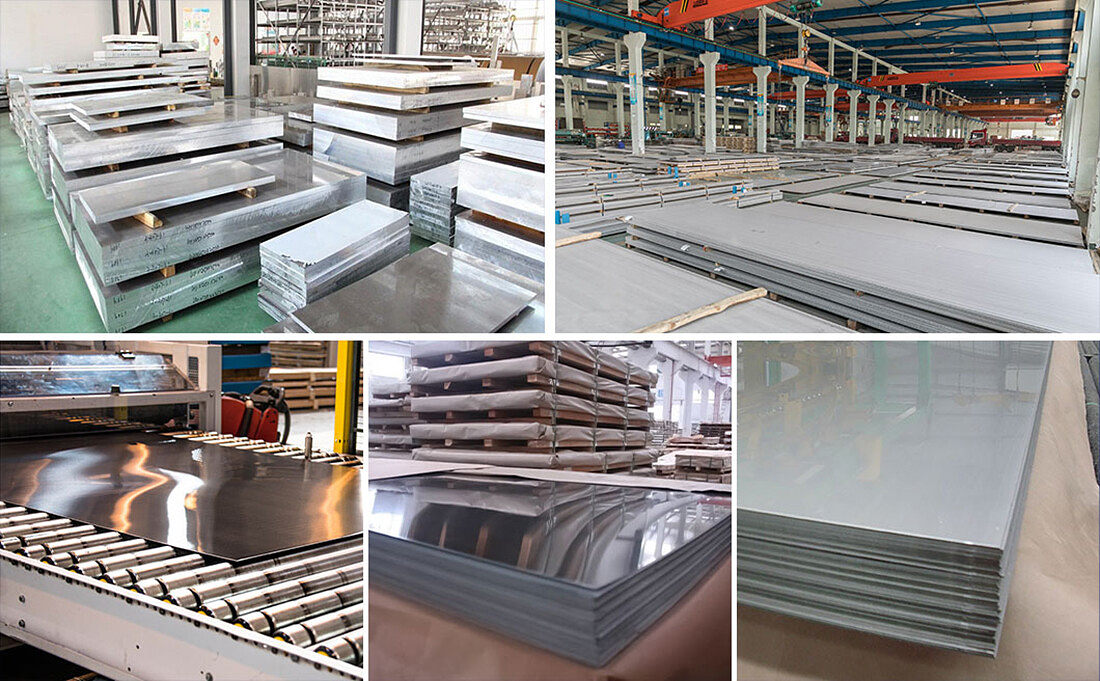

| Verpackung | Bündel, PVC-Beutel, Nylongürtel, Kabelbinder, Standard-Export seetüchtig Paket oder als Anfrage. |

| Bearbeitungsservice | Biegen, Schweißen, Abwickeln, Stanzen, Schneiden und andere. |

| Toleranz | ±1% |

| MOQ | {MOQ} |

Zusammensetzung von rostfreiem Stahl

Stahl ist eine Legierung aus Eisen und Kohlenstoff. Nichtrostende Stähle sind Stähle mit mindestens 10,5% Chrom, weniger als 1,2% Kohlenstoff und anderen Legierungselementen. Die Korrosionsbeständigkeit von rostfreiem Stahl und

Die mechanischen Eigenschaften können durch Zugabe anderer Elemente wie Nickel, Molybdän, Titan, Niob, Mangan usw. weiter verbessert werden.

| Klasse | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 201 | ≤0.15 | ≤0.75 | 5.5~7.5 | ≤0.060 | ≤0.03 | 16.00~18.00 | 3.5~5.5 | – | – | 0.08 |

| 202 | ≤0.15 | ≤1.00 | 7.5~10.00 | ≤0.060 | ≤0.03 | 17.00~19.00 | 4.0~6.0 | – | ≤0.25 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 6.00~8.00 | – | ||

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 17.00~19.00 | 8.00~10.00 | – | ||

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 8.00~10.50 | – | ||

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18.00~20.00 | 9.00~13.00 | – | ||

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 24.00~26.00 | 19.00~22.00 | – | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 10.00~14.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 12.00~15.00 | 2.00~3.00 | ||

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17.00~19.00 | 9.00~13.00 | – | ||

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | 16.00~18.00 | – | |||

| 2205 | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.015 | 22.00~23.00 | 4.5~6.5 | 2.5~3.5 | ||

| 2507 | ≤0.03 | ≤0.08 | ≤1.20 | ≤0.035 | ≤0.015 | 24.00~26.00 | 6.00~8.00 | 3.0~5.0 | ||

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.035 | 19.00~23.00 | 23.00~28.00 | 4.0~5.0 | 1.0~2.0 | |

| INCONEL028 | ≤0.03 | ≤1.00 | ≤2.50 | ≤0.030 | ≤0.030 | ≤28.0 | ≤34.0 | ≤4.0 | ≤1.4 | |

| MONEL400 | ≤0.30 | ≤0.5 | ≤2.00 | – | ≤0.024 | – | ≥63.0 | – | ≤34.0 | |

| INCONEL800 | ≤0.10 | ≤1.00 | ≤1.50 | – | ≤0.015 | ≤23.0 | ≤35 | 4.0~5.0 | – | ≤0.75 |

Auswahl der Oberfläche