The characteristics of 316 stainless steel mainly include the following points:

Corrosion resistance: 316 stainless steel belongs to austenitic stainless steel, containing a high proportion of nickel and molybdenum, so it has excellent corrosion resistance, especially in chloride ion environment, which can effectively prevent stress corrosion and pitting. Compared with other types of stainless steel (such as 304), 316 stainless steel is more resistant to marine environment and chemical corrosion.

High temperature resistance: 316 stainless steel has good high temperature resistance and can be used for a long time in an environment up to 870 degrees Celsius. Short-term use at higher temperatures will not affect its characteristics.

Good formability and weldability: Another significant advantage of 316 stainless steel is its excellent formability and weldability. During the manufacturing process, whether it is stamping, stretching or bending, the material can maintain excellent processing performance. This provides great convenience for the production of parts with complex shapes. In terms of welding, 316 stainless steel also has excellent weldability. After welding, the corrosion resistance of the material will not only not decrease, but will be enhanced due to the corrosion-resistant modified layer formed.

Chemical composition: The chemical composition of SUS316 stainless steel is the basis for determining its performance. Its main alloying elements include 16%-18% chromium, 10%-14% nickel and 2%-3% molybdenum. Chromium improves the corrosion resistance of the material, nickel improves the toughness and plasticity of the material, and the addition of molybdenum significantly improves the corrosion resistance of stainless steel in chlorides. In addition, SUS316 also contains trace amounts of carbon, silicon, manganese and phosphorus, making its physical and chemical properties meet the material standards.

Application scenarios and uses: Due to the stainless properties and good mechanical properties of 316 stainless steel, its application scenarios are very wide. In aerospace, marine engineering, and even the medical industry, SUS316 is everywhere. Specifically, in the chemical industry, SUS316 is widely used in equipment such as reaction vessels, pipelines, and valves; in the aerospace field, 316 can be used as a structural part; in the field of medical devices, due to its excellent antibacterial and corrosion resistance, 316 has become an optional material for medical devices such as surgical instruments and implants; in the field of food processing, due to its corrosion resistance and easy cleaning, 316 is used to manufacture storage tanks, pipelines and equipment parts.

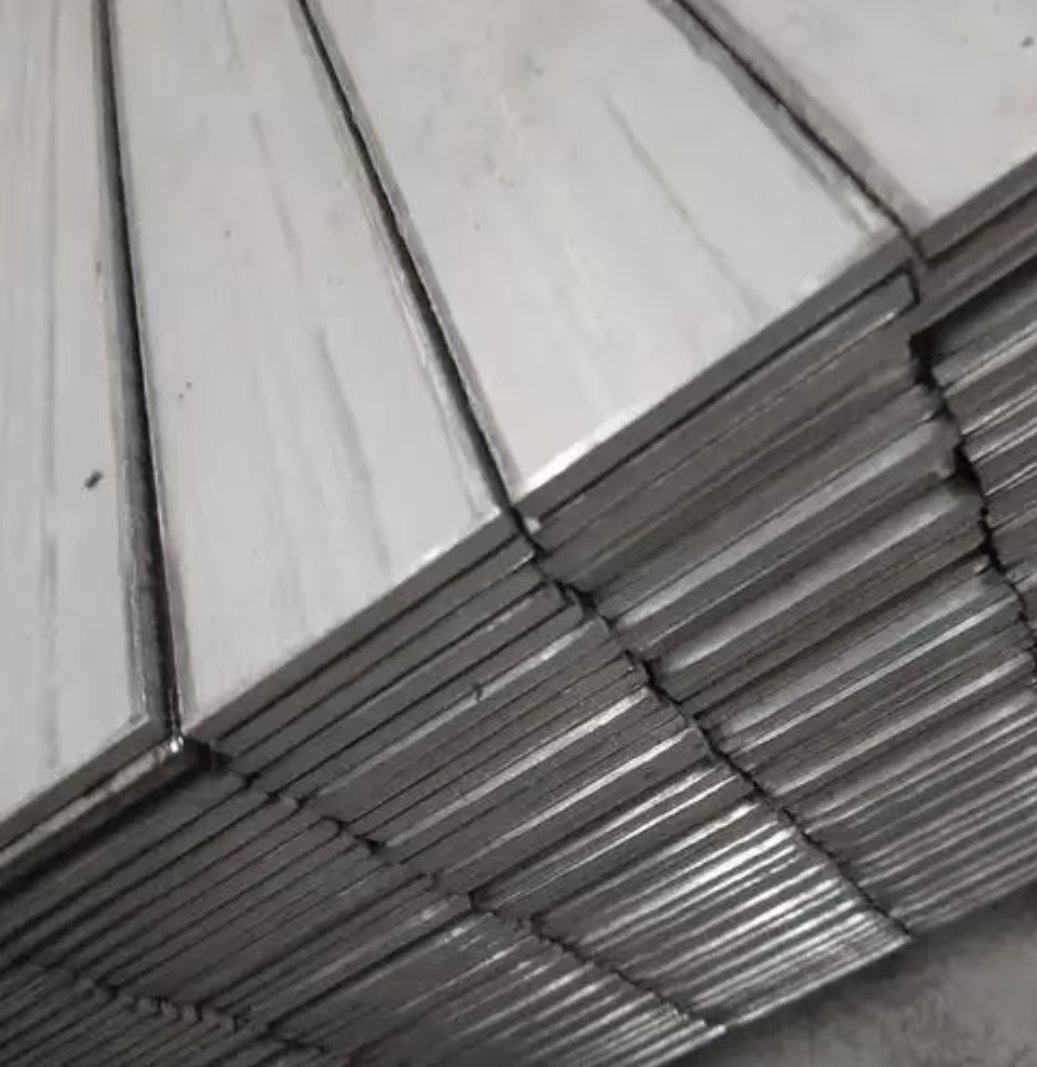

| اسم المنتج | قضيب مسطح من الفولاذ المقاوم للصدأ المسطح |

| النوع | مدرفلة على الساخن |

| العرض | 12-300 مم |

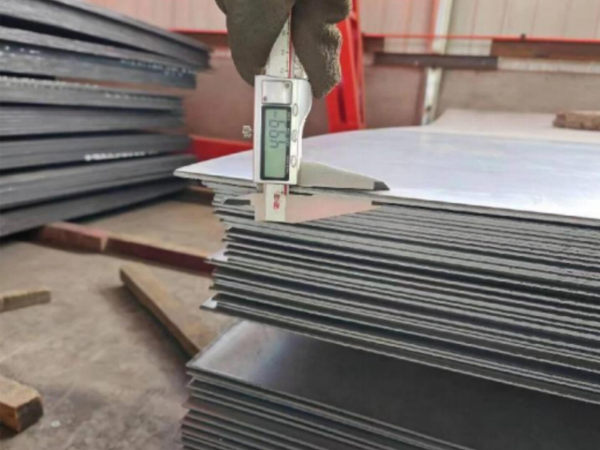

| السُمك | 3-60 مم |

| الطول | 10-6000 مم |

| تشطيب السطح | 2 ب، ب ب، خط الشعر، رقم 4 |

| الصف | 201، 304، 304، 304S، 316، 316L، إلخ. |

| قياسي | ASME، ASTM، ASTM، EN، BS، GB، DIN، JIS، إلخ |

| شروط الدفع | T/T، 30% من القيمة المدفوعة مسبقًا بعد توقيع عقد البيع في غضون ثلاثة أيام عمل، والرصيد مقابل نسخة من B/L |